Products

-

Taisin Light-adopted 3D printer ISL1100

-

Taisin Light-adoptive 3D printer SLA200

-

Taisin Light-adoptive 3D printer SLA800

-

Taisin high-speed and high-precision processing center for processing parts TX-V8

-

Taisin Metal 3D printer ISLM600QN

-

Taisin Light-adopted 3D printer SLA6036

-

Taisin Metal 3D printer ISLM500D

-

Taisin Metal 3D printer ISLM800QN

-

Taisin high-speed five-axis processing center TX-UC400

-

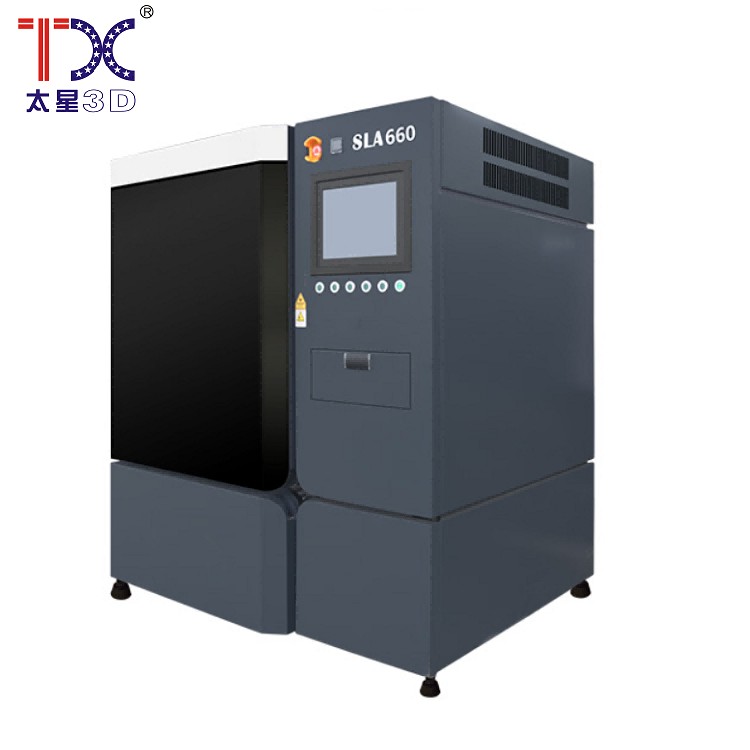

Taisin Light-adopted 3D printer SLA660Lite

-

Taisin Metal 3D printer SLM160

-

Taisin Metal 3D printer ISLM350DN

-

Taisin Metal 3D printer ISLM420DN

-

Taisin Light-adoptive 3D printer SLA300

-

Taisin Gravity-milling machine EMC-650

-

Taisin Light-adoptive 3D printer SLA880

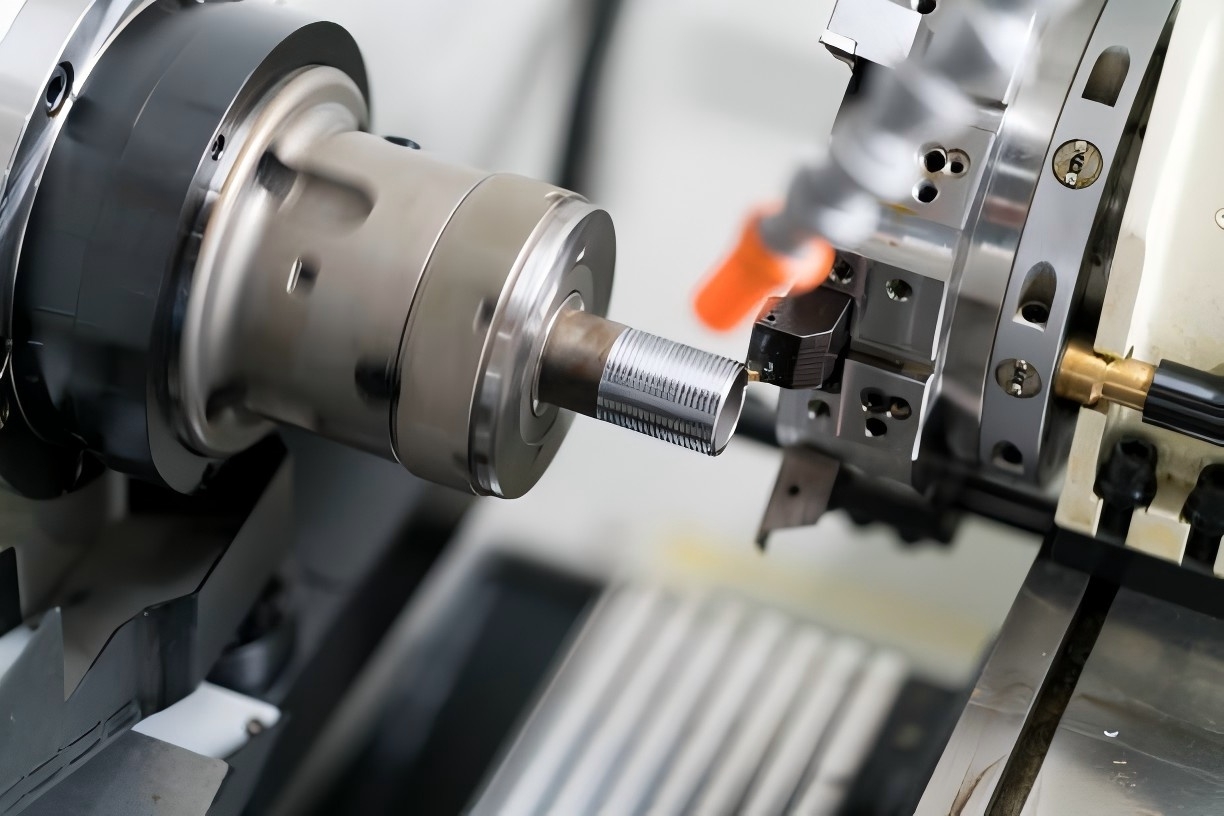

Taisin Vertical CNC TXLC-500 CNC

A vertically tokure machine (WTL) is one of the most traditional types of machine tools. They are ideal for heavy processing of medium and large parts. As technology develops, vertical turning machines become more universal. Our vertical turning machines increase performance due to stable processing of thin -walled blanks and workproof preparations. The base and column of the box -like type form a highly reliable and rigid structure. The hull of the spindle with the flange structure minimizes the effect of thermal deformation and vibration, providing stable and accurate cutting.

Description

marker

Introduction of the product

A vertically tokure machine (WTL) is one of the most traditional types of machine tools. They are ideal for heavy processing of medium and large parts. As technology develops, vertical turning machines become more universal. Our vertical turning machines increase performance due to stable processing of thin -walled blanks and workproof preparations. The base and column of the box -like type form a highly reliable and rigid structure. The hull of the spindle with the flange structure minimizes the effect of thermal deformation and vibration, providing stable and accurate cutting.

Details about the product

A vertically tokure machine (WTL) is one of the most traditional types of machine tools. They are ideal for heavy processing of medium and large parts. As technology develops, vertical turning machines become more universal. Our vertical turning machines increase performance due to stable processing of thin -walled blanks and workproof preparations. The base and column of the box -like type form a highly reliable and rigid structure. The hull of the spindle with the flange structure minimizes the effect of thermal deformation and vibration, providing stable and accurate cutting.

maximum. Moving along the X axis:

700 mm

maximum. Moving along the Y axis:

550 mm

maximum. Moving along the axis Z:

500 mm

The maximum work of the workpiece:

6800 kg

Application:

Precise press form, auto parts

Processing:

Surface milling, drilling holes, threading

The main technical parameters

| thing | thing | ||||

| Maximum rotation diameter | Maximum rotation diameter | ||||

| The maximum turn height | The maximum turn height | ||||

| The maximum rotation diameter | The maximum rotation diameter | ||||

| The diameter of the spindle hole | The diameter of the spindle hole | ||||

| Maximum diameter of the processing of the bar | Maximum diameter of the processing of the bar | ||||

| Type and code of the end of the spindle | Type and code of the end of the spindle | ||||

| Spindle box with one spindle spindle speed range | Spindle box with one spindle spindle speed range | rpm/nm | |||

| The power of the main engine is 30 minutes/continuously | The power of the main engine is 30 minutes/continuously | kW | |||

| The output power of the second engine is 30 minutes/continuously | The output power of the second engine is 30 minutes/continuously | kW | |||

| S standard diameter of the cartridge | S standard diameter of the cartridge | inch | |||

| Speed speed X | Speed speed X | ||||

| High speed along the axis z | High speed along the axis z | ||||

| High speed of moving along the axis W | High speed of moving along the axis W | ||||

| Moving along the axis x | Moving along the axis x | ||||

| Moving along the axis z | Moving along the axis z | ||||

| tool | tool | ||||

| The size of the outer ring The diameter of the storage mandrel | The size of the outer ring | mm | |||

| The diameter of the storage mandrel | mm | ||||

| Choose the nearest tool | Choose the nearest tool | ||||

| W eight g Rose weight | W eight g Rose weight | KG | |||

| Maximum disco of discs | Maximum disco of discs | KG | |||

| Form length*width*height | Form length*width*height | mm | |||

Technical characteristics IDEN160

Laser system

Laser system type laser Voloconium laser

Wavelength 1064 nm

Laser power 500 W

re -coating system

The re -coating system system for applying the coating: the scraper distributes the powder in two directions.

The thickness of the normal layer is 0.03 mm.

Fast the thickness of the layer 0.03 ~ 0.10 mm.

The thickness of the precision production layer is 0.02 ~ 0.03 mm.

Optical scan system

Optical and scanning stain (diameter @ 1/e²) 0.05 ~ 0.15 mm

Scanning galvanometer Scanlab

Part scan speed 2.0 m/s (recommended)

Partial jump speed 10.0 m/s (recommended)

Estimated speed of production: 1200 dental crowns/24 hours, 75 dental braces/24 hours.

Protection system

Shield system gas protection nitrogen, argon (active metal materials must be protected by argon)

Stream regulator: intellectual adjustment 0-3 l/min.

Dusting control and an effective protective gas circulation system

Dust removal fourth level of removal and dust cleaning

Make a vat

The standard volume of VAT is about 5 liters.

Production platform XY 160 mm (x) × 160 mm (Y) (excluding fillets, etc.)

A axis Z 200 mm (including the thickness of the substrate)

The maximum weight of the part is 10 kg.

Fast replacement of the substrate assembly and disassembly without holes for the screws and fast replacement of the transition compartment

Precise Servigator of the drive engine

Type of heating: precision heating of resistance wires

Molding materials: pure titanium, titanium alloy, cobalt chromium alloy, etc.

Management software

Ethernet, TCP/IP, IEEE802.3 network software software

ISLM 4.0 control software, special software for dental production

3Dlayer data processing software (multi -level processing software with three -dimensional support)

Data CLI file, SLC file, STL file

Installation conditions

Equipment conditions of power supply 220 V (± 10 %) alternating current, 50/60 Hz, single -phase, 16 A.

Environmental temperature 20-26 ° C

Relative humidity is below 40%, without frost.

Equipment size is 1.10 m (w) × 1.30 m (g) × 1.85 m (c)

Equipment weight is about 1000 kg.

Warranty period

A guarantee for a laser 5000 hours or 12 months (depending on what will come earlier)

The life of the entire machine is 12 months from the date of installation.