Products

-

Taisin Metal 3D printer SLM280

-

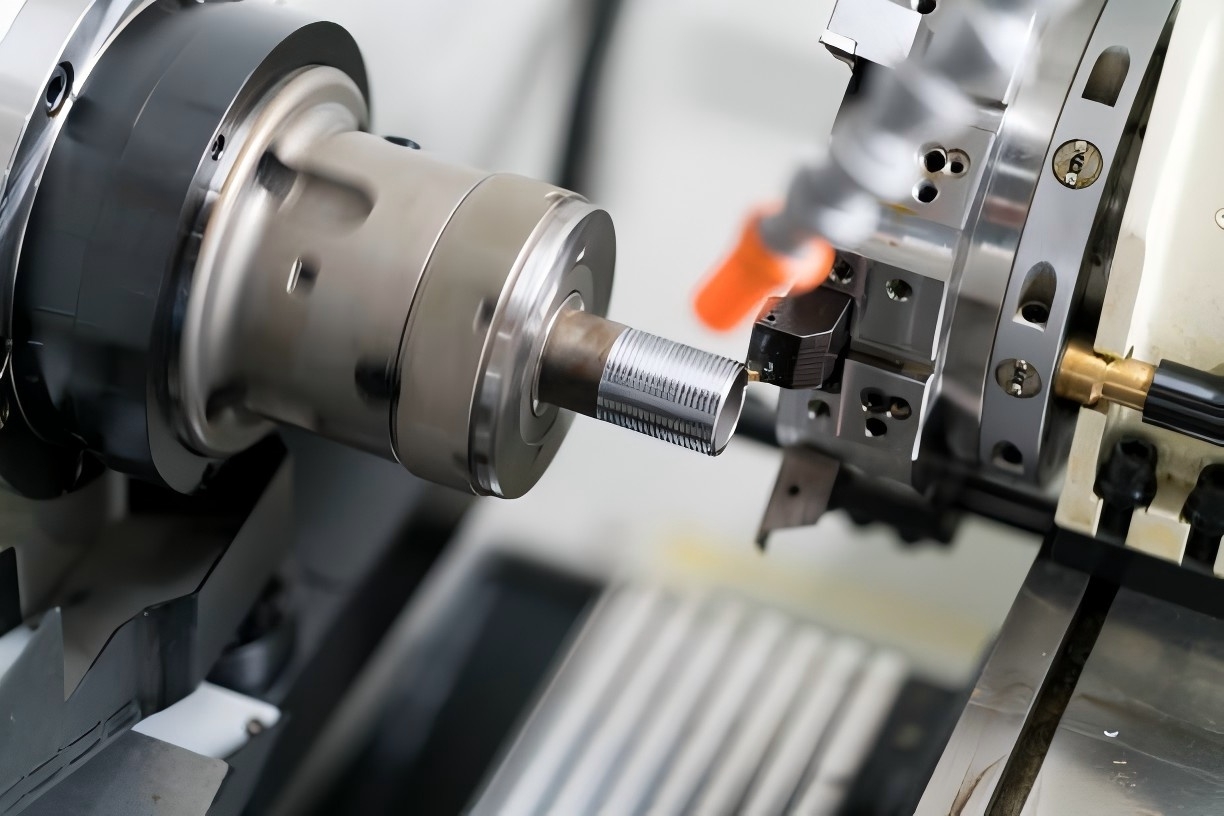

Taisin Vertical CNC TXLC-500 CNC

-

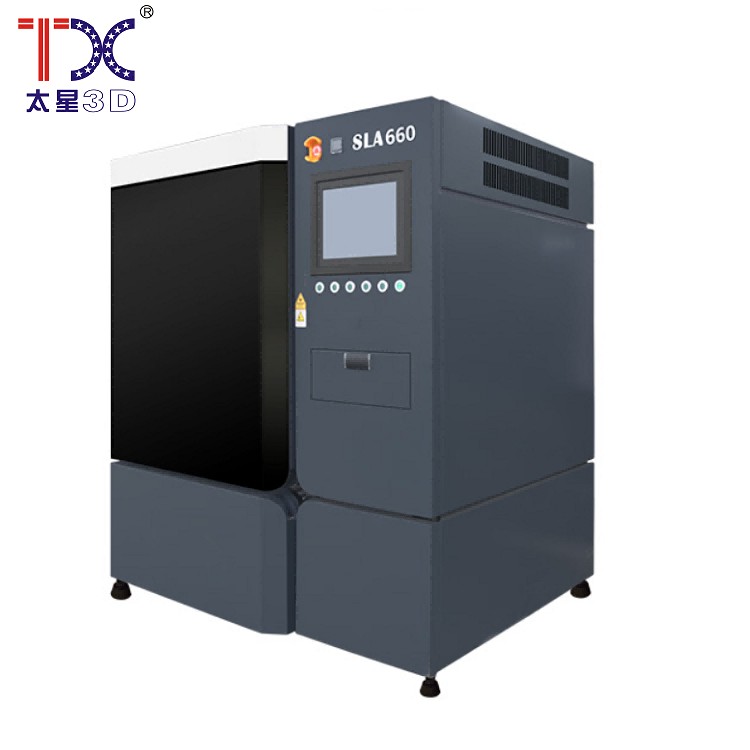

Taisin Light-adoptive 3D printer SLA550

-

Taisin Light-adoptive 3D printer SLA550EX

-

Taisin Light-adopted 3D printer ISL1100

-

Taisin portal processing center with CNC TXM-9038

-

Taisin Gravity-milling machine EMC-650

-

Taisin Light-adoptive 3D printer SLA500

-

Taisin horizontal processing center with CNC High accuracy HMC TXHD-630

-

Taisin Light-adopted 3D printer SLA1300D

-

Taisin high-speed five-axis processing center TX-UC400

-

Taisin Light-adoptive 3D printer SLA450

-

Taisin Light-adoptive 3D printer SLA200

-

Taisin Metal 3D printer ISLM350DN

-

Taisin processing center for drilling and cutting threads TXT-800

-

Taisin Metal 3D printer SLM160

Taisin high-speed and high-precision processing center for processing parts TX-V8

A high -speed and high -precision processing center for parts is a CNC processing equipment, which combines the functions of milling, drilling, carving, boring and others. It is specially designed for high -precision and high -speed production. Its nucleus has a high stiffness design and a high -speed spindle equipped with precision linear guides and ball screws to ensure stability and accuracy during processing. The processing center is equipped with a rapid shift system and an effective design of chips removal, which significantly increases the processing efficiency and the level of automation of production. It is widely used in the aerospace industry, automobile details, precision tools, the production of press forms and other areas and is suitable for processing complex forms and high-precision parts with high demand.

Description

marker

Introduction of the product

A high -speed and high -precision processing center for parts is a CNC processing equipment, which combines the functions of milling, drilling, carving, boring and others. It is specially designed for high -precision and high -speed production. Its nucleus has a high stiffness design and a high -speed spindle equipped with precision linear guides and ball screws to ensure stability and accuracy during processing. The processing center is equipped with a rapid shift system and an effective design of chips removal, which significantly increases the processing efficiency and the level of automation of production. It is widely used in the aerospace industry, automobile details, precision tools, the production of press forms and other areas and is suitable for processing complex forms and high-precision parts with high demand.

Details about the product

The main design of the machine is made of high -quality Meehanite cast iron. A strong design of the machine increases the stability of the casting to compression. · Spindle with direct connection, high speed, low vibration, low noise and low temperature growth. Can withstand prolonged operations of high -speed processing;

Three axes are equipped with linear roller guides, which provide better rigidity and carrying capacity. · Three axes are driven directly from the engines, which completely eliminates the backlash;

The design of a high -speed tool change mechanism in combination with preliminary control and a highly effective cutting system allows you to carry out work on changing the tool.

The main technical parameters

| Project unit | TX-V8 | TX-V10 | TX-VI370 | ||

| journey | |||||

| Moving along the axis x | mm | 800 | 1000 | 1300 | |

| Moving along the Y axis | mm | 500 | 600 | 700 | |

| Moving along the axis z | mm | 550 | 600 | 700 | |

| Distance from the end of the spindle to the desktop | mm | 120-670 | 120-720 | 120-820 | |

| Distance from the center of the spindle to the column | mm | 605 | 655 | 770 | |

| workbench | |||||

| The size of the workbench | mm | 1000 × 550 | 1100x600 | 1400*700 | |

| Maximum load | KG | 450 | 450 | 700 | |

| The dimensions of the T-shaped groove | 5*18t*80 | 5*18t*100 | 5*18t*125 | ||

| Spindle | |||||

| Speed (special) | R.P.M | 12000 | 12000 | 12000 | |

| Spindle speed (standard configuration) | RPM | 12000-15000 | 12000-15000 | 12000-15000 | |

| Spindle power | KW | 7.5 | 11 | 11 | |

| Characteristics of the end of the spindle | BT-40 | BT-40 | BT-40 | ||

| Feed | |||||

| Accelerated supply on the XYZ axis | mm/mn | 48000 | 36000 | 36000 | |

| Three -axis cutting | mm/min | 1-10000 | 1-10000 | 1-10000 | |

| another | |||||

| The power of the three -axle engine | KW | 02/2/3 | 33/3 | 3/33 | |

| Positioning accuracy | mm | ± 0.005/300 | ± 0.005/300 | ± 0.005/300 | |

| The accuracy of repetition | mm | ± 0.003300 | ± 0.003/300 | ± 0.003/300 | |

| controller | FanucMitsubish | ||||

| Cutting Mizuharaura | HP | 1/2 | 1/2 | 1/2 | |

| The need for power | KVA | 20 | 25 | 30 | |

| Air pressure characteristics | Bar | 0.6mpa | = 0.6mpa | > 0.6mpa | |

| Mechanical weight | KG | 4500 | 5500 | 8500 | |

| The size of the column of the car | mm | 2500 × 2300 × 2500 | 2700 × 2400 × 2600 | 3300 × 2600 × 3000 | |

Technical characteristics IDEN160

Laser system

Laser system type laser Voloconium laser

Wavelength 1064 nm

Laser power 500 W

re -coating system

The re -coating system system for applying the coating: the scraper distributes the powder in two directions.

The thickness of the normal layer is 0.03 mm.

Fast the thickness of the layer 0.03 ~ 0.10 mm.

The thickness of the precision production layer is 0.02 ~ 0.03 mm.

Optical scan system

Optical and scanning stain (diameter @ 1/e²) 0.05 ~ 0.15 mm

Scanning galvanometer Scanlab

Part scan speed 2.0 m/s (recommended)

Partial jump speed 10.0 m/s (recommended)

Estimated speed of production: 1200 dental crowns/24 hours, 75 dental braces/24 hours.

Protection system

Shield system gas protection nitrogen, argon (active metal materials must be protected by argon)

Stream regulator: intellectual adjustment 0-3 l/min.

Dusting control and an effective protective gas circulation system

Dust removal fourth level of removal and dust cleaning

Make a vat

The standard volume of VAT is about 5 liters.

Production platform XY 160 mm (x) × 160 mm (Y) (excluding fillets, etc.)

A axis Z 200 mm (including the thickness of the substrate)

The maximum weight of the part is 10 kg.

Fast replacement of the substrate assembly and disassembly without holes for the screws and fast replacement of the transition compartment

Precise Servigator of the drive engine

Type of heating: precision heating of resistance wires

Molding materials: pure titanium, titanium alloy, cobalt chromium alloy, etc.

Management software

Ethernet, TCP/IP, IEEE802.3 network software software

ISLM 4.0 control software, special software for dental production

3Dlayer data processing software (multi -level processing software with three -dimensional support)

Data CLI file, SLC file, STL file

Installation conditions

Equipment conditions of power supply 220 V (± 10 %) alternating current, 50/60 Hz, single -phase, 16 A.

Environmental temperature 20-26 ° C

Relative humidity is below 40%, without frost.

Equipment size is 1.10 m (w) × 1.30 m (g) × 1.85 m (c)

Equipment weight is about 1000 kg.

Warranty period

A guarantee for a laser 5000 hours or 12 months (depending on what will come earlier)

The life of the entire machine is 12 months from the date of installation.