Products

-

Taisin Light-adoptive 3D printer SLA550

-

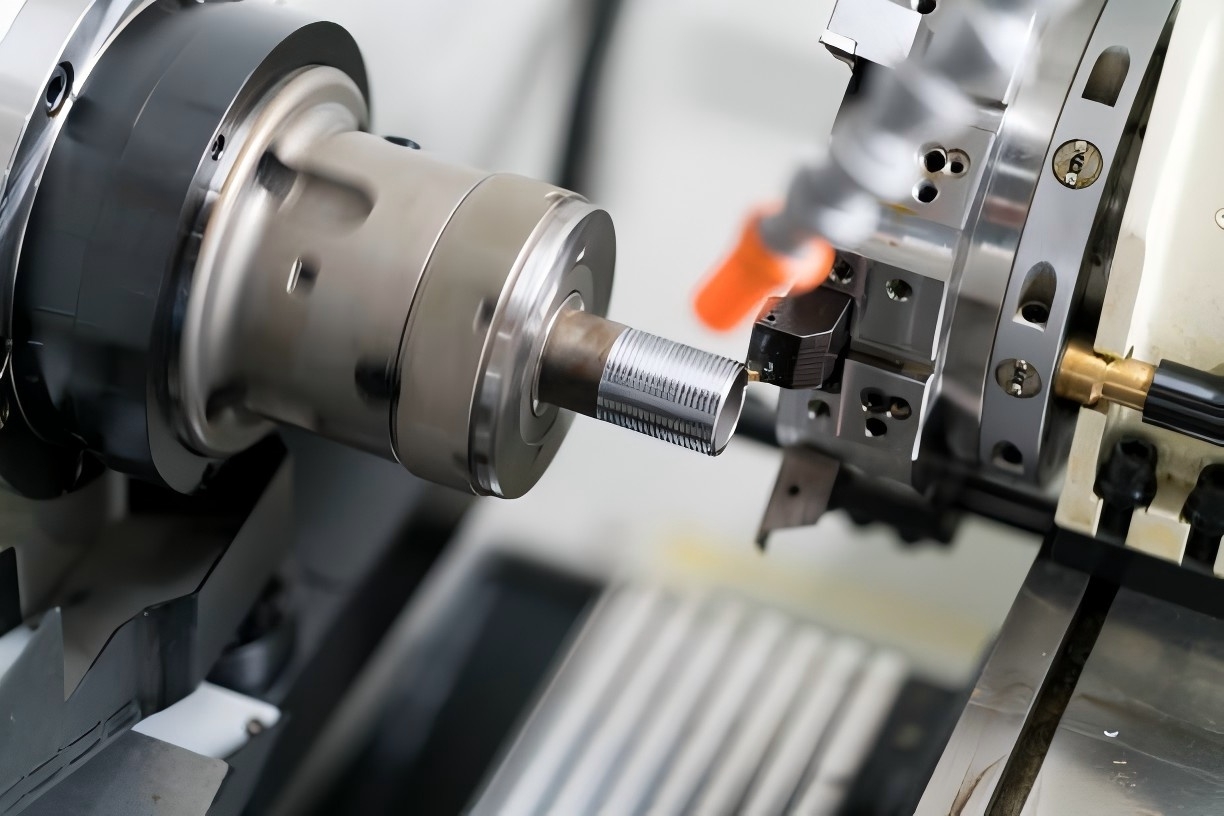

Taisin high-precision vertical processing center with CNC VMC TXP-1890

-

Taisin Metal 3D printer ISLM350DN

-

Taisin Light-adoptive 3D printer SLA450

-

Taisin Light-adoptive 3D printer SLA500

-

Taisin portal processing center with CNC TXM-9038

-

Taisin high-speed and high-precision processing center for processing parts TX-V8

-

Taisin three-wire rail molding machine of high stiffness TX-6027

-

Taisin Light-adoptive 3D printer SLA550EX

-

Taisin high-speed drilling and threaded machine TX-T6

-

Taisin Metal 3D printer ISLM600QN

-

Taisin horizontal processing center with CNC High accuracy HMC TXHD-630

-

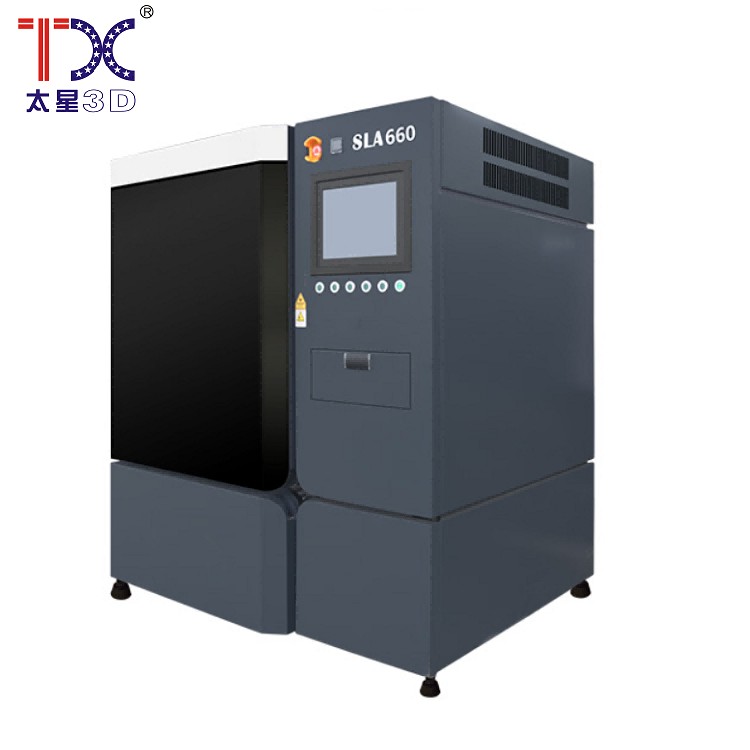

Taisin Light-adopted 3D printer SLA660Lite

-

Taisin Light-adopted 3D printer SLA1300D

-

Taisin Light-adoptive 3D printer SLA800

-

Taisin Metal 3D printer SLM280

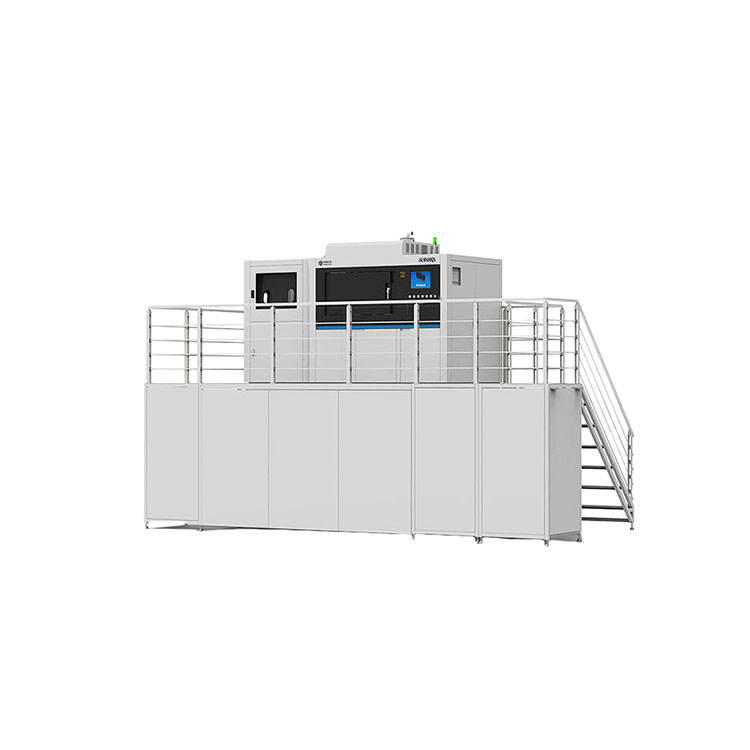

Taisin Metal 3D printer ISLM800QN

Selective laser melting of metals (SLM)-This is a 3D printing technology in which metal powder is used for direct printing of metal parts. When printing, the scraper applies a layer of metal powder to the supporting plate of the forming cylinder, and the laser beam selectively melts the powder in accordance with the transverse section of each layer of the part for processing the current layer. After the sintering of one layer is completed, the lifting system reduces the height of one layer of cross section. The video for the distribution of the powder distributes another layer of metal powder into the formed layer of cross section and sins the next layer. This is the layer by the layer. Until the whole part is in a way. The entire molding process is carried out in a technological chamber, vacuumed or filled with protective gas to prevent metal reaction with other gases at high temperatures.

Description

marker

Selective laser melting of metals (SLM)-This is a 3D printing technology in which metal powder is used for direct printing of metal parts. When printing, the scraper applies a layer of metal powder to the supporting plate of the forming cylinder, and the laser beam selectively melts the powder in accordance with the transverse section of each layer of the part for processing the current layer. After the sintering of one layer is completed, the lifting system reduces the height of one layer of cross section. The video for the distribution of the powder distributes another layer of metal powder into the formed layer of cross section and sins the next layer. This is the layer by the layer. Until the whole part is in a way. The entire molding process is carried out in a technological chamber, vacuumed or filled with protective gas to prevent metal reaction with other gases at high temperatures.

In the technology of selective laser melting of metalsTaisinA laser with a high energy density and a small diameter of the spot is used, which can complete the manufacture of complex parts, the manufacture of which with conventional methods would require weeks or even months, for an extremely short cycle. Formed parts not only have accurate dimensional accuracy, high strength and high mass density, but also have excellent mechanical properties and other aspects. It is mainly used for the rapid manufacture of high -precision and high -quality metal parts.

Key features

High speed, high accuracy, high quality

Metal 3D printer Taisin · SLM series

Formed parts have the best surface quality without polishing.

Formed parts have high accuracy and are used for the manufacture of accurate prototypes.

The direct production of metal functional parts without intermediate processes, which greatly simplifies the production process.

It has a metallurgical structure, high density (> 99%), excellent mechanical properties and allows us to exclude the need for subsequent processing.

Details can be made in a matter of minutes or hours, depending on the size and complexity of the part.

Functional details of a complex geometric shape (for example, latches, living loops) can be made directly.

The material has a wide range of application, and its metal powder can be various single -component materials or multicomponent materials.

Especially suitable for individual production of functional parts by single or small batches.

Technical characteristics of the ISLM800QN

| LAzer system Laser system | Laser type Volokon laser × 4 Wavelength 1064 nm Laser power (500 W/1000 W) × 4 |

| WITHRasking out of re -coating Re -coating system | The coating method: the scraper distributes the powder in two directions. Powder supply mode: the powder falling system and the powder circuit circulation system automatically serve the powder. The thickness of the normal layer is 0.05 mm. Quickly produce a layer with a thickness of 0.05 ~ 0.15 mm. The thickness of the precision production layer is 0.02 ~ 0.05 mm. |

| Optical scan system Optical and scanning | Light spot (diameter @ 1/e²) 0.06 ~ 0.20 mm Scanning galvanometer high -speed scanning galvanometer × 4 Part scan speed 4.0 m/s (recommended) Partial jump speed ≥10.0 m/s. |

| WITHProtection project Shield system | Protective gas nitrogen, argon (active metal materials must be protected by argon) Stream regulator: intellectual adjustment 0-5 l/min. Dusting control and an effective protective gas circulation system |

| Make a vat Construction VAT | The standard volume is about 500 liters. Production platform XY 800 mm (x) × 700 mm (y) (excluding rounding holes for screws, etc.) The axis z 1000 mm (including the thickness of the substrate) The maximum weight of the part is 300 kg. Type of heating: precision heating of resistance wires Molding materials: stainless steel, foundry, titanium alloy, aluminum alloy, cobalt chromium alloy, nickel alloy, copper, etc. |

| PRogram management SOFTWARE | Type of Ethernet, TCP/IP, IEEE802.3 ISLM production (Presto SLM) 3Dlayer data processing software (multi -level processing software with three -dimensional support) Data CLI file, SLC file, STL file |

| Installation conditions Installation conditions | Power supply 380V (± 10%) of alternating current 50/60Hz, three -phase, 30a Environmental temperature 20-26 ° C Relative humidity is below 40%, without frost. Equipment size 3.15 m (W) × 2.55 m (d) × 3.95 m (c) Equipment weight is about 12,000 kg (excluding the lifting platform). |

| Warranty period GUARANTEE | Laser 5000 hours or 12 months (depending on what will come earlier) The life of the entire machine is 12 months from the date of installation. |