Products

-

Taisin Metal 3D printer ISLM350DN

-

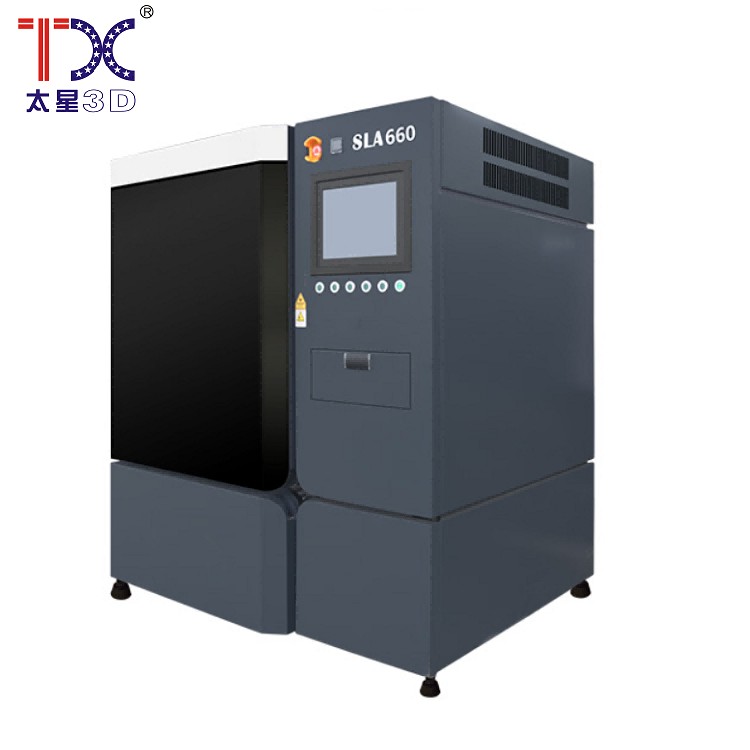

Taisin Light-adoptive 3D printer SLA550

-

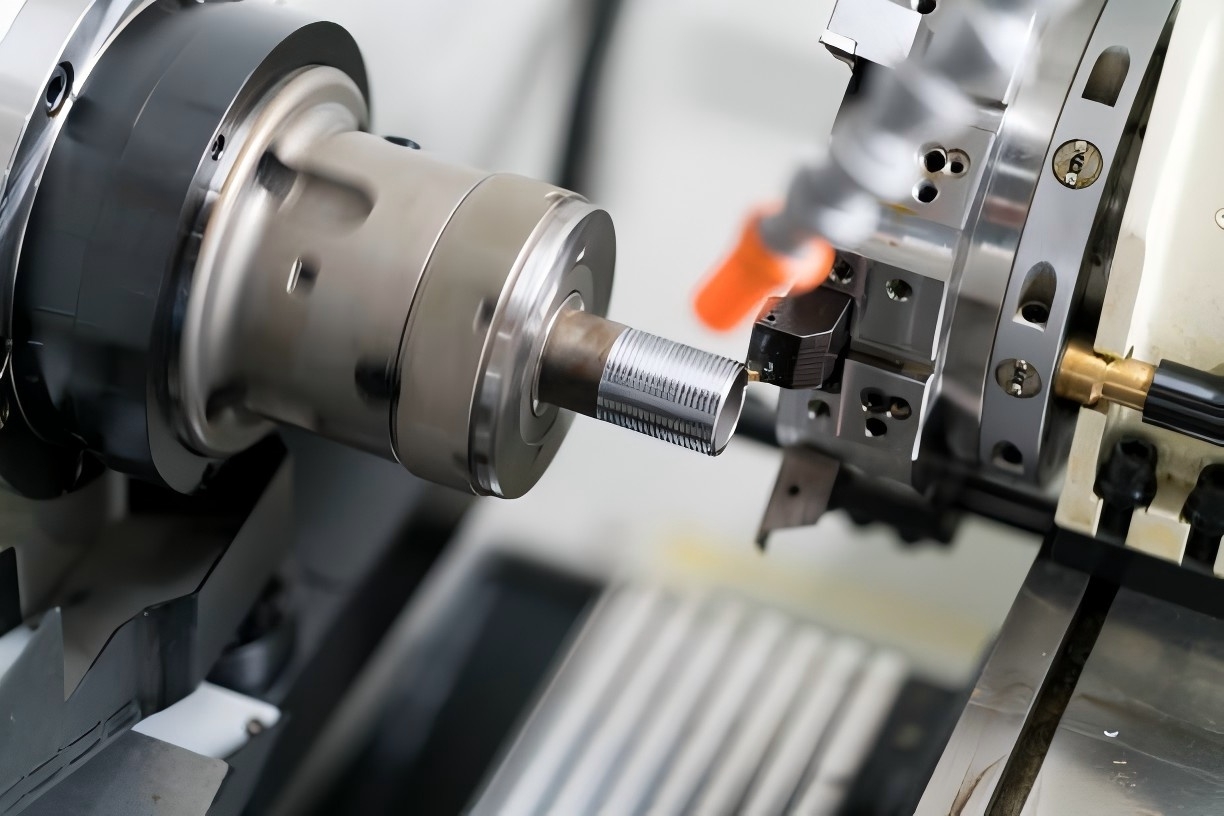

Taisin high-speed drilling and threaded machine TX-T6

-

Taisin Metal 3D printer ISLM420DN

-

Taisin three-wire rail molding machine of high stiffness TX-6027

-

Taisin horizontal processing center with CNC High accuracy HMC TXHD-630

-

Taisin Light-adoptive 3D printer SLA500

-

Taisin Metal 3D printer ISLM500D

-

Taisin Light-adoptive 3D printer SLA300

-

Taisin Metal 3D printer SLM160

-

Taisin Vertical CNC TXLC-500 CNC

-

Taisin Light-adopted 3D printer SLA1300D

-

Taisin processing center for drilling and cutting threads TXT-800

-

Taisin Light-adoptive 3D printer SLA550EX

-

Taisin high-speed and high-precision processing center for processing parts TX-V8

-

Taisin Light-adoptive 3D printer SLA1600D

Taisin portal processing center with CNC TXM-9038

A two -column vertical processing adapts to the characteristics of traditional two -column machines with high rigidity, a symmetrical structure and high stability. Through the analysis of elements, the structure of the main components is optimized, the dynamic characteristics of the product are improved and the perfect combination of high power, high torque, high efficiency and high -precision processing is achieved. It is suitable for large -scale sectors of heavy processing, such as shipbuilding, metallurgy and petrochemistry.

Description

marker

Introduction of the product

A two -column vertical processing adapts to the characteristics of traditional two -column machines with high rigidity, a symmetrical structure and high stability. Through the analysis of elements, the structure of the main components is optimized, the dynamic characteristics of the product are improved and the perfect combination of high power, high torque, high efficiency and high -precision processing is achieved. It is suitable for large -scale sectors of heavy processing, such as shipbuilding, metallurgy and petrochemistry.

Details about the product

A two -column vertical processing adapts to the characteristics of traditional two -column machines with high rigidity, a symmetrical structure and high stability. Through the analysis of elements, the structure of the main components is optimized, the dynamic characteristics of the product are improved and the perfect combination of high power, high torque, high efficiency and high -precision processing is achieved. It is suitable for large -scale sectors of heavy processing, such as shipbuilding, metallurgy and petrochemistry.

① Basic structure

Compared to the design with two guides, stiffness increases by 50% compared to the design with four guides, it is more symmetrical and evenly distributed, which reduces power losses caused by the resistance of a multi -ruble slider with a width of 3 m; , a linear guide with a base of 2.1 m. The optimal ratio range is 0.7.

② Portal structure of the mobile nut

The X axis is driven by a mobile nut with a three -point support in the middle to maintain the accuracy of rotation of the SHVP. At the same time, it has a greater carrying capacity and good resistance to vibrations during cutting. This can improve the dynamic characteristics of the machines and increase the accuracy, stability and life of the machine tools.

③ square plunger

Larger size 500*500, original size 460*460. This is a stronger design; The built -in design of a direct connection reduces power consumption when transmitting a spindle to a spindle from the engine.

④ Slide show function

A large, strong design guarantees that the upper part of the lift is firmly held by three sliding guides, and the lower part is supported by four standard guides.

⑤ nitrogen counterweight

Reduce the load on the engine and the power of the SHVP bearing, increase the service life of the shvp and engine, and the acceleration of the Z axis provides the accuracy of processing.

⑥ beam structure

Step L-shaped structure increases the stiffness, a concave C-shaped structure provides better resistance to bending;

Design of large sections; Of course element analysis.

⑦ System of the support frame with a ballpoint gear

⑧ STOPLACE Structure

A super -stroke column 1.28 m long reduces the overall vibration during cutting and makes the machine stable.

The main technical parameters

| Model | TXM-9038 | |||

| Topic | Specification | unit | 9000 | |

| travel

| Ox X | mm | 3800 | |

| axis y | mm | 1250 (best 1500) | ||

| axis z | mm | 350-1600 | ||

| Spindle's nose to layout | mm | High-strength roller linear guide X/Y, directing the T-shaped type along the axis Z | ||

| Trequic guide | 3800 | |||

| The width of the door | Square ram (500x500) | |||

| Type of RAM | 8800*3000 | |||

| Work sheet

| Line size (length*width) | mm | 52 | |

| Maximum load on the workbench | T | 15-28*200 | ||

| T-shaped groove | mm | BBT-50 | ||

|

Spindle | Spindle type | type | 6000 | |

| Spindle speed | Speed | Right in DS | ||

| Spindle drive method | June 10, 2010 | |||

|

| Fast movement (x/y/z) | m/min | 6 | |

| Cutting speed (x/y/z) | m/min | 24 (options: 40/60) | ||

| The speed of feed | Air traffic control | 22/26 (140-286NM) | ||

| Tool change device | Spindle engine | KW | 6/3/3 (38/36/36NM) | |

| Three -axis servomotor | KW | 0.05/0.03/0.015 | ||

| engine

| accuracy | mm | 0.03/0.02/0.01 | |

| Repeatability | mm | 60 | ||

| accuracy

| The need for power | Qian Fuan | 6^8 | |

| Air pressure requirements | kg/cm2 | 19600*7000*6320 | ||

| necessary force | Dimensional dimensions (length*width*height) | mm | 91 | |

| gross weight | T | 9000 | ||

Technical characteristics IDEN160

Laser system

Laser system type laser Voloconium laser

Wavelength 1064 nm

Laser power 500 W

re -coating system

The re -coating system system for applying the coating: the scraper distributes the powder in two directions.

The thickness of the normal layer is 0.03 mm.

Fast the thickness of the layer 0.03 ~ 0.10 mm.

The thickness of the precision production layer is 0.02 ~ 0.03 mm.

Optical scan system

Optical and scanning stain (diameter @ 1/e²) 0.05 ~ 0.15 mm

Scanning galvanometer Scanlab

Part scan speed 2.0 m/s (recommended)

Partial jump speed 10.0 m/s (recommended)

Estimated speed of production: 1200 dental crowns/24 hours, 75 dental braces/24 hours.

Protection system

Shield system gas protection nitrogen, argon (active metal materials must be protected by argon)

Stream regulator: intellectual adjustment 0-3 l/min.

Dusting control and an effective protective gas circulation system

Dust removal fourth level of removal and dust cleaning

Make a vat

The standard volume of VAT is about 5 liters.

Production platform XY 160 mm (x) × 160 mm (Y) (excluding fillets, etc.)

A axis Z 200 mm (including the thickness of the substrate)

The maximum weight of the part is 10 kg.

Fast replacement of the substrate assembly and disassembly without holes for the screws and fast replacement of the transition compartment

Precise Servigator of the drive engine

Type of heating: precision heating of resistance wires

Molding materials: pure titanium, titanium alloy, cobalt chromium alloy, etc.

Management software

Ethernet, TCP/IP, IEEE802.3 network software software

ISLM 4.0 control software, special software for dental production

3Dlayer data processing software (multi -level processing software with three -dimensional support)

Data CLI file, SLC file, STL file

Installation conditions

Equipment conditions of power supply 220 V (± 10 %) alternating current, 50/60 Hz, single -phase, 16 A.

Environmental temperature 20-26 ° C

Relative humidity is below 40%, without frost.

Equipment size is 1.10 m (w) × 1.30 m (g) × 1.85 m (c)

Equipment weight is about 1000 kg.

Warranty period

A guarantee for a laser 5000 hours or 12 months (depending on what will come earlier)

The life of the entire machine is 12 months from the date of installation.