Products

-

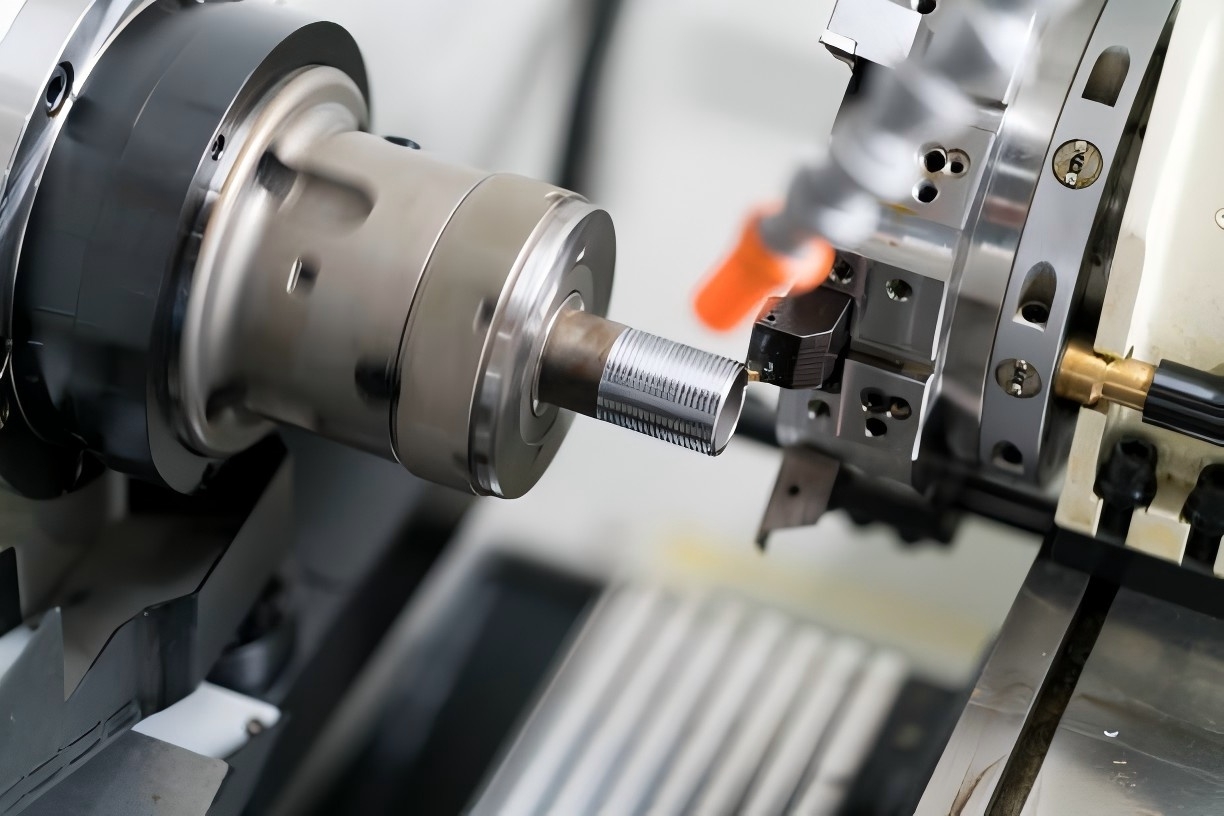

Taisin Gravity-milling machine EMC-650

-

Taisin three-wire rail molding machine of high stiffness TX-6027

-

Taisin drilling and threaded-cutting machine with CNC TXT-700

-

Taisin Light-adoptive 3D printer SLA800

-

Taisin high-precision vertical processing center with CNC VMC TXP-1890

-

Taisin Light-adopted 3D printer SLA660Lite

-

Taisin horizontal processing center with CNC High accuracy HMC TXHD-630

-

Taisin processing center for drilling and cutting threads TXT-800

-

Taisin Light-adopted 3D printer SLA6036

-

Taisin Light-adoptive 3D printer SLA880

-

Taisin Light-adoptive 3D printer SLA1900D

-

Taisin Light-adoptive 3D printer SLA550

-

Taisin Light-adoptive 3D printer SLA450

-

Taisin Metal 3D printer IDEN160

-

Taisin Vertical CNC TXLC-500 CNC

-

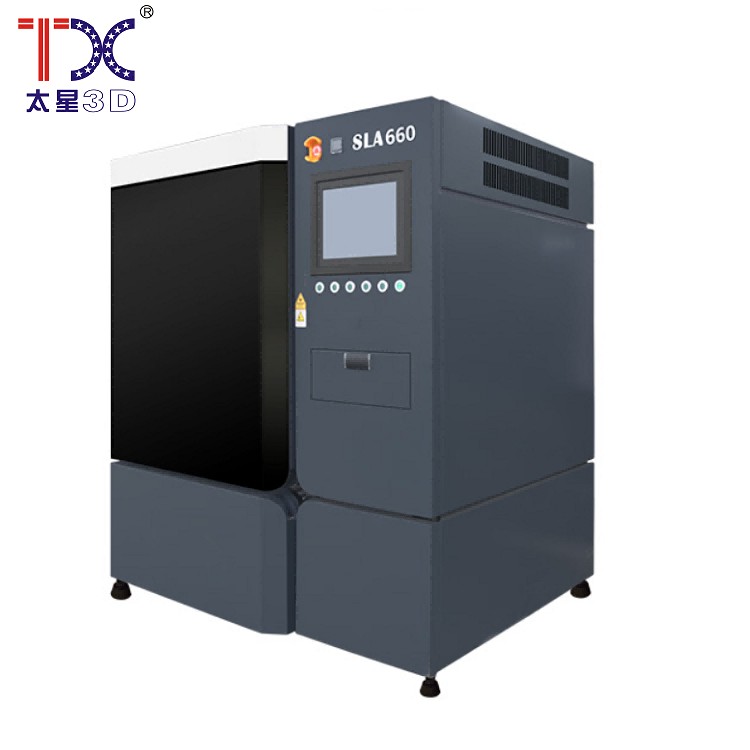

Taisin Light-adopted 3D printer SLA660

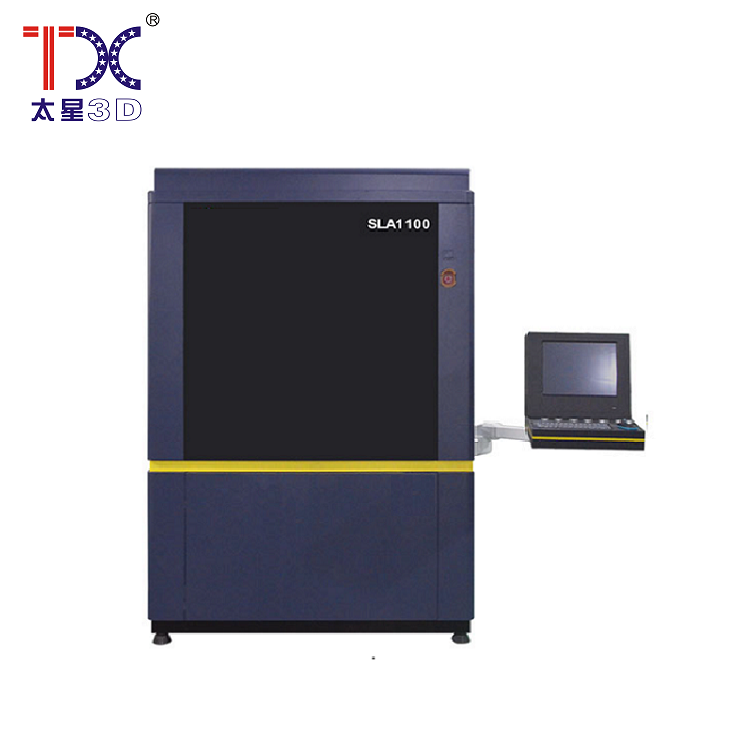

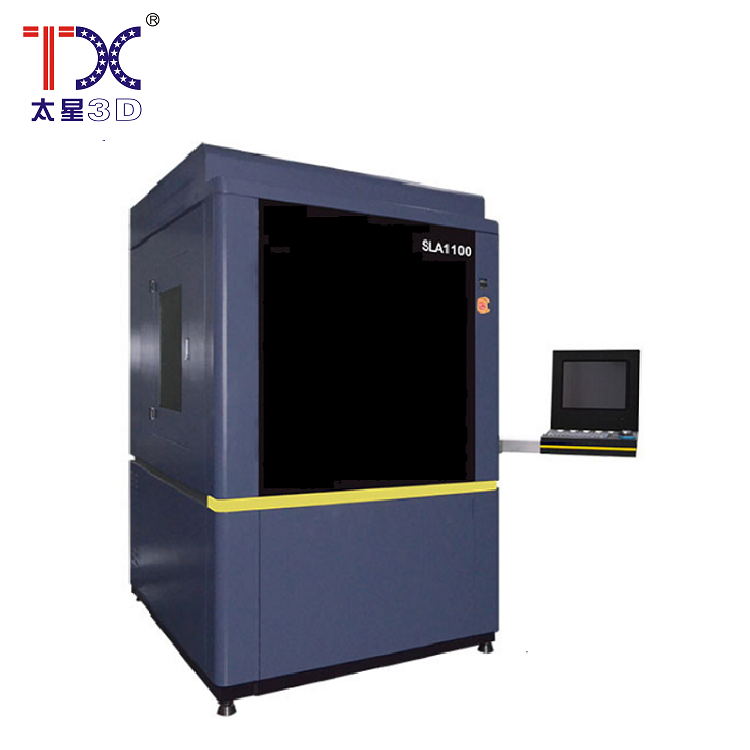

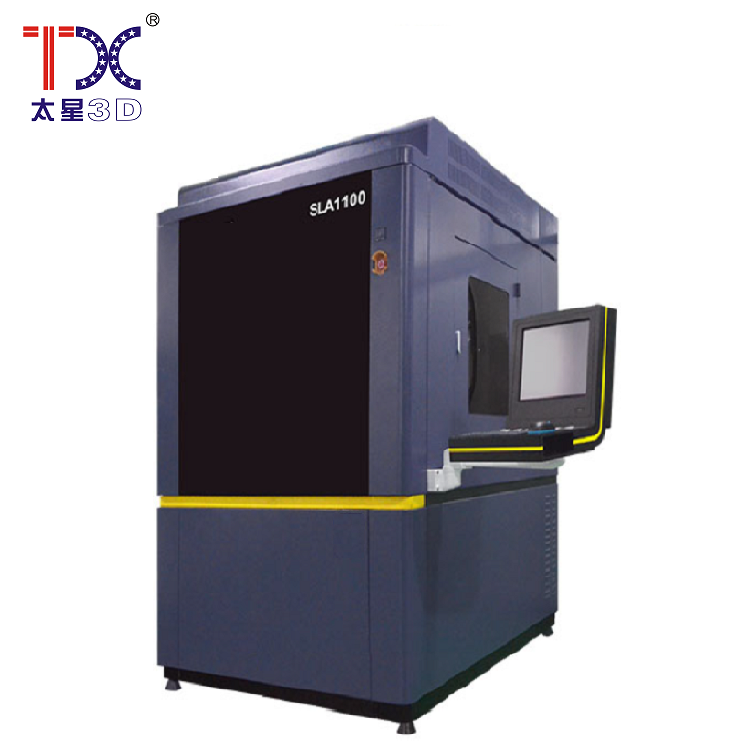

Taisin Light-adopted 3D printer ISL1100

Stereolithography (SLA) is a high-speed and high-precision 3D printing technology. Details are printed using a UV laser and a liquid photopolymer, cured by UV radiation-“photopolymer”. The laser beam is controlled to scan the surface of the liquid resin, so that the surface of the liquid resin hardens, forming the scanned film of the cross section of the part. After curing one layer, cover the newly formed layer with another layer of liquid resin and continue scanning to harden and combine it with the cross section of the previously rejected part. This happens forward and backward, a layer by a layer to print a full three -dimensional part.

Description

marker

Introduction of the product

Stereolithography (SLA) is a high-speed and high-precision 3D printing technology. Details are printed using a UV laser and a liquid photopolymer, cured by UV radiation-“photopolymer”. The laser beam is controlled to scan the surface of the liquid resin, so that the surface of the liquid resin hardens, forming the scanned film of the cross section of the part. After curing one layer, cover the newly formed layer with another layer of liquid resin and continue scanning to harden and combine it with the cross section of the previously rejected part. This happens forward and backward, a layer by a layer to print a full three -dimensional part.

Details about the product

Molded parts with the highest detail and the quality of the smooth surface

Accuracy up to 0.05 mm for the manufacture of precision prototypes.

Details can be made in a matter of minutes or hours, depending on the size and complexity of the part.

The possibility of manufacturing various parts and compound nodes.

Smolish materials differ in strength, detail, color, transparency and heat resistance.

Technical characteristics ISLA1100

| Category | Specification |

| Laser system | Number of lasers: single laser (standard)/double laser (individually: isla1100d) Lazer type: solid -state laser with diode pump (nd: yvo₄) Wave length: 354.7 nm Lazer power: 1000/2000/3000 MW |

| Re -coating system | Coating method: intellectual positional-vacuum-adsorption coating. Normal layer thickness: 0.1 mm. The thickness of the fast production layer: 0.1-0.15 mm. The thickness of the layer of precision production: 0.05–0.1 mm. |

| Optical scan system | The diameter of the spot (@1/e²): 0.10–0.16 mm (normal), 0.10-0.50 mm (dynamic scaling) Scanning galvanometer: high -speed scanning galvanometer Part scan speed: 6.0 m/s (recommended) Part jump speed: 10.0 m /s (recommended) |

| The reference speed of production | 100-230 g/h (Super | Single laser) 150–350 g/h (Super × 2 | Double laser) |

| Lifting system | Repeated positioning accuracy: ± 0.01 mm. Lifting engine: high -precision cervical. Reference platform: marble reference platform. |

| Resin tank | Standard volume: about 785 liters at 600 mm (Z) Production platform XY: 1000 mm (x) × 1000 mm (Y) A axis Z: 600 mm (standardly) / 500 mm (by individual order) / 400 mm (by individual order) Maximum weight: 120 kg at 600 mm (Z) Smol heating method: precision heating wire resistance. |

| Photosensitive resin | ZR680 (saturated white), ZR710 (strong white), ZR820 (high transparency), Realabs (persistent yellow), redwood (red yoma) |

| Management software | Network type: Ethernet, TCP/IP, IEEE802.3 Management software: ISLA (Zero 5.0) Production software Data processing software: 3DLAYER Data interface: CLI file, SLC file, STL file |

| Installation conditions | Power Subject: 200–240 V, 50/60 Hz, single -phase, 5/17 A. Environmental temperature: 20–26 ° C. Relative humidity: less than 40 %, without freezing. The dimensions of the device: 1.60 m (width) × 1.90 m (depth). ) × 2.30 m (height) (without a computer rack) Equipment weight: approximately 1800 kg |

| Warranty period | Laser: 5000 hours or 12 months (depending on what will come earlier). Car assembly: 12 months from the date of installation. |