What are the trends in the market for CNC milling machines?

2025-02-01

- Innovation in the field of automation and control

- The influence of artificial intelligence and the Internet of things

- Environmental stability and energy efficiency

- Flexibility and personalization of production

- Maintenance and training of personnel

- Economic aspects and implementation of new technologies

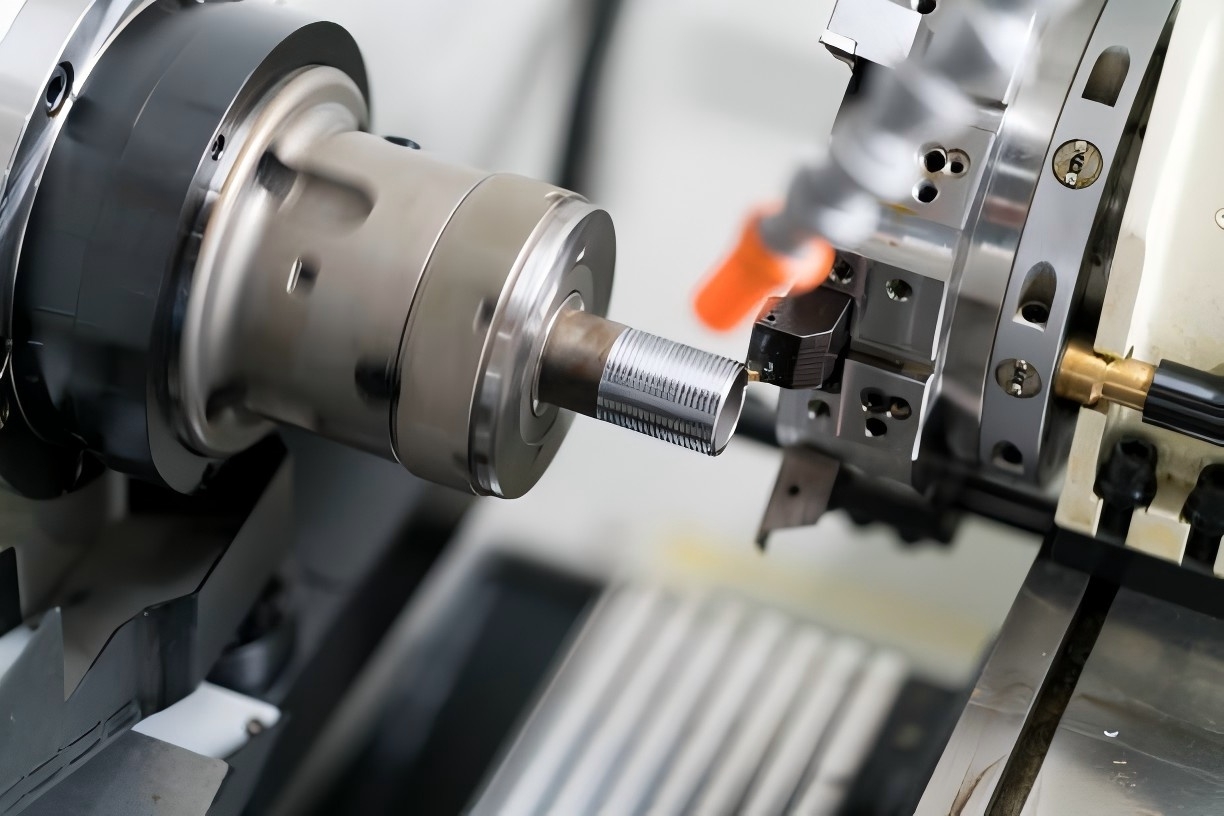

The sphere of milling machines with numerical control (CNC) develops rapidly and continues to surprise with new innovations and technological achievements. Modern production is increasingly introducing these machines into their processes to increase efficiency and reduce production costs. The main trends in this market are associated with different aspects: automation, increase in performance, decreasing costs and increasing product quality. The introduction of new technologies, such as artificial intelligence and the Internet, changes the usual idea of the possibilities of CNC milling machines. This article is designed to reveal the most important trends in this area and their influence on industry industry, paying special attention to the advantages of useCNC Pyatores.

Innovation in the field of automation and control

Automation of production processes remains the main trend that significantly changes the approach to the use of CNC milling machines. Innovative control systems can significantly improve the accuracy and stability of processing. The use of predictive services, the integration of machine learning and artificial intelligence help minimize the number of mistakes, which leads to a decrease in the amount of marriage and improving the quality of products. The possibility of remote control and control of milling machines is also of great importance. Operators can monitor the operation of equipment from anywhere in the world, which significantly increases the flexibility of the production process.

CNC milling plantsThey play a special role here, because their multifunctionality and versatility allow them to process the most complex details with high accuracy. Such machines become indispensable in industries, where complex geometry of parts is required. Thanks to improved management systems, they can several times reduce the time costs of production operations without losing exactly or quality. ApplicationCNC PyatoresIn automated systems, it allows you to reach a new level of optimization of production processes.

The influence of artificial intelligence and the Internet of things

An integral part of the production process is the use of artificial intelligence (AI) and the Internet of things (IOT). These technologies repeatedly increase the effectiveness of the work of milling machines with CNC. AI allows you to analyze the huge arrays of the data obtained during the operation of the machine, and on the basis of this analysis to optimize its work. The use of intelligent management systems leads to a decrease in the number of downtime and more efficient use of resources.

On the other hand, IoT provides the connection of machine tools between themselves and with other production systems, which allows you to monitor all stages of the process in real time. This is especially true for enterprises striving for integrated and digital production lines.CNC Pyato -axial milling machineAs an element of this system, it can provide a high degree of automation and interaction, accelerating the receipt of the final product from the idea to the final product.

Environmental stability and energy efficiency

Modern challenges in the field of ecology and reasonable use of resources were not bypassed and the industry of milling machines with CNC. The need for reducing energy costs and minimizing the negative impact on the environment is becoming increasingly tangible. Manufacturers of machine tools are actively looking for solutions to reduce energy consumption without loss of performance.

Experts develop waste processing systems, form non -waste production cycles, modernize machine tools to achieve maximum energy efficiency. The use of advanced materials also helps to increase environmental stability. For example, useCNC Pyatores, made using such technologies, allows not only to reduce the carbon trace, but also to significantly reduce production costs due to the more rational use of materials.

Flexibility and personalization of production

Today, enterprises strive to adapt to dynamic market conditions, which makes flexibility and personalization to the most important aspects of production. The ability to quickly reconfigure machines for the production of various batches of products allows enterprises to be more competitive. Adjusting for individual requests of customers becomes one of the competitive privileges.

CNC Pyato -axial milling machineIt has the widest opportunities for customization of the production process. Due to its characteristics, it can easily switch between different tasks, ensuring the manufacture of products according to individual requirements without significant time renovation costs. Such opportunities significantly reduce temporary costs and allow you to quickly respond to market requests.

Maintenance and training of personnel

The growth of automation and the introduction of the latest technologies require appropriate staff training. Training of operators with the principles of working with modern CNC milling machines is an important aspect, which often determines the success of introducing innovation in production. At the same time, the need for regular maintenance of equipment remains critical to maintain it in working condition.

Modern solutions include training programs, simulation simulators and specialized courses, which allows you to qualitatively improve the qualifications of workers. To support CNC milling machines in working condition, special software is also used that can diagnose problems before their occurrence. This is especially important forCNC milling plants with CNCWhere every detail and correct work of all mechanisms play a key role in the general result.

Economic aspects and implementation of new technologies

The introduction of new technologies in production is always associated with certain economic investments. However, in the case of CNC milling machines, these investments pay off quite quickly by increasing the performance and quality of products. Modern systems allow reducing production costs, which in turn launches a profit increase cycle.

Investments inCNC Pyato -axial milling machineThey can become strategically substantiated, as such machines can significantly expand production capabilities. The transition to new technologies always entails structural changes within enterprises, which, as a rule, is accompanied by an increase in market competitiveness. Companies that have bet on innovation in production gain an advantage through the possibility of introducing new production approaches and adaptation to changing market conditions.

Thus, CNC milling machines are currently a powerful tool that allows enterprises to remain competitive, effectively use resources and respond to changes in demand. Attention paid to innovation, environmental friendliness and staff training can significantly increase the efficiency of processes in production and improve the quality of the products offered to the market.