What are the advantages of high -speed cutting at vertical processing centers with CNC?

2024-11-12

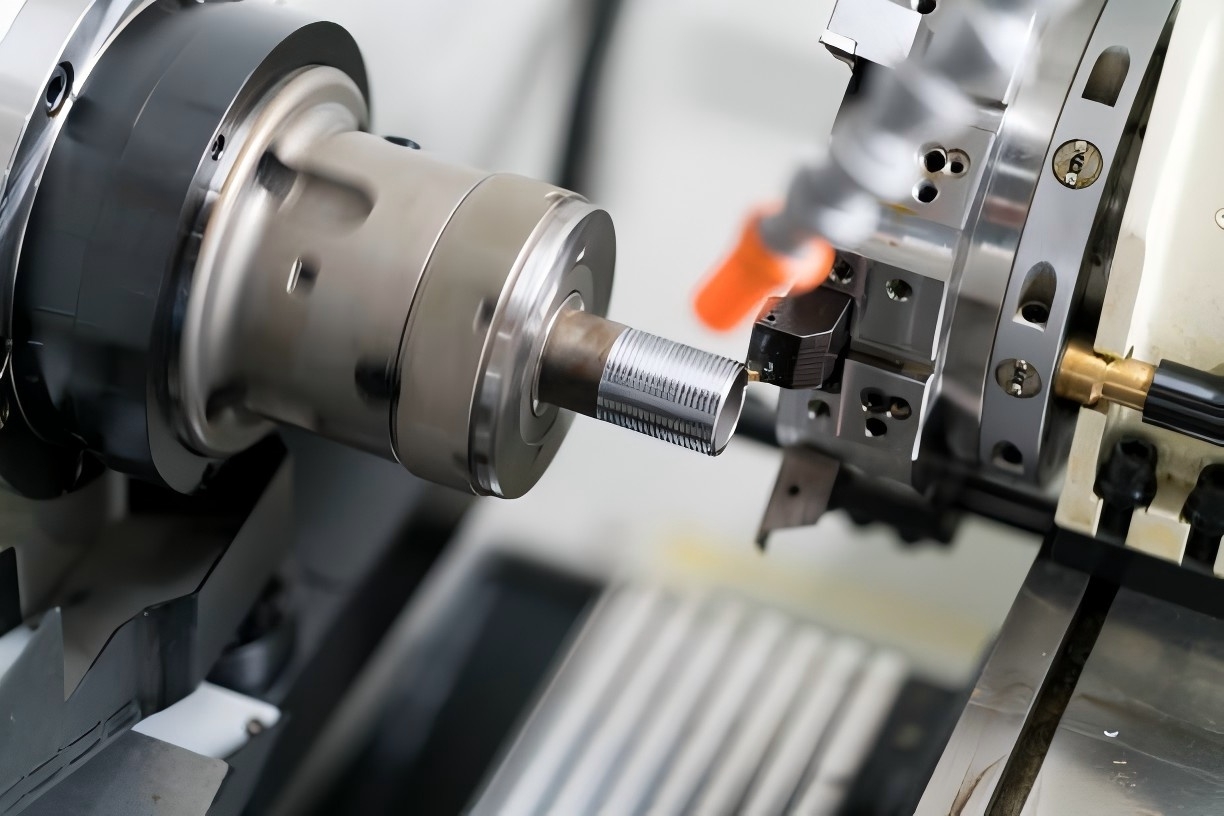

Vertical processing center of high -speed cutting on the one hand. When a vertical processing center cuts at high speed, the temperature of the tool and workpiece can be maintained at a low level, which in many cases extends the life of the tool. On the other hand, with high -speed cutting, the cutting volume is small. The time of hooking the cutting edge is extremely short. This means that the supply time is shorter than the heat distribution time.

The low cutting forces lead to a small and constant deviation of the tool. This, in combination with the constant availability of reserves necessary for each tool and operation, is one of the prerequisites for safe processing.

Due to the low cutting depth with high -speed cutting, the radial force on the tool and spindle is small, which reduces the wear of the bearing of the spindle, guides and the SHVP. High -speed cutting and axial milling are also a good combination. It practically does not affect Spindle bearings. With this use, you can use longer tools with a minimum risk of vibration.

High performance of small parts of small sizes. For example, with draft, half -sewing and finishing processing, it provides good efficiency when the total speed of the material is relatively low.

High -speed cutting allows you to achieve high final processing productivity and achieve good surface quality. The surface roughness values are often lower than R o, 2.

A vertical processing center uses high -speed cutting, which allows you to cut thin -walled parts. Use high -speed cutting to process thin walls. Since the cutting time is short, the effect and deformation of the thin walls decrease.

Improve the geometric accuracy of the form. The assembly will become easier and faster. High -speed cutting allows you to achieve good surface texture and geometric accuracy. If you devote more time cutting, manual polishing time can be significantly reduced.

Vertical processing centers use high -speed cutting, and some processing processes, such as hardening, electrochemical processing and electric processing (EDM), can be significantly reduced. This reduces investment costs and simplifies logistics. Replacing electric processing (EDM) for cutting also increases the durability, resistance of the tool and the quality of the press form.