What are the advantages of a five coordinate center?

2025-01-20

Five -coordinate processing centers are becoming increasingly popular in various industries due to their universality and the ability to process complex parts with high accuracy and efficiency. These machines open new horizons for engineers and manufacturers, providing the opportunity to create products of complex shape, while minimizing the costs of time and material. In the conditions of the modern technological market, where innovation and competitiveness play a key role, the possibilities offered by five -coordinate centers become a decisive factor in achieving success. In this article, we will consider the main advantages of using five -coordinate centers, their influence on the production process, as well as the features of their application in various fields.

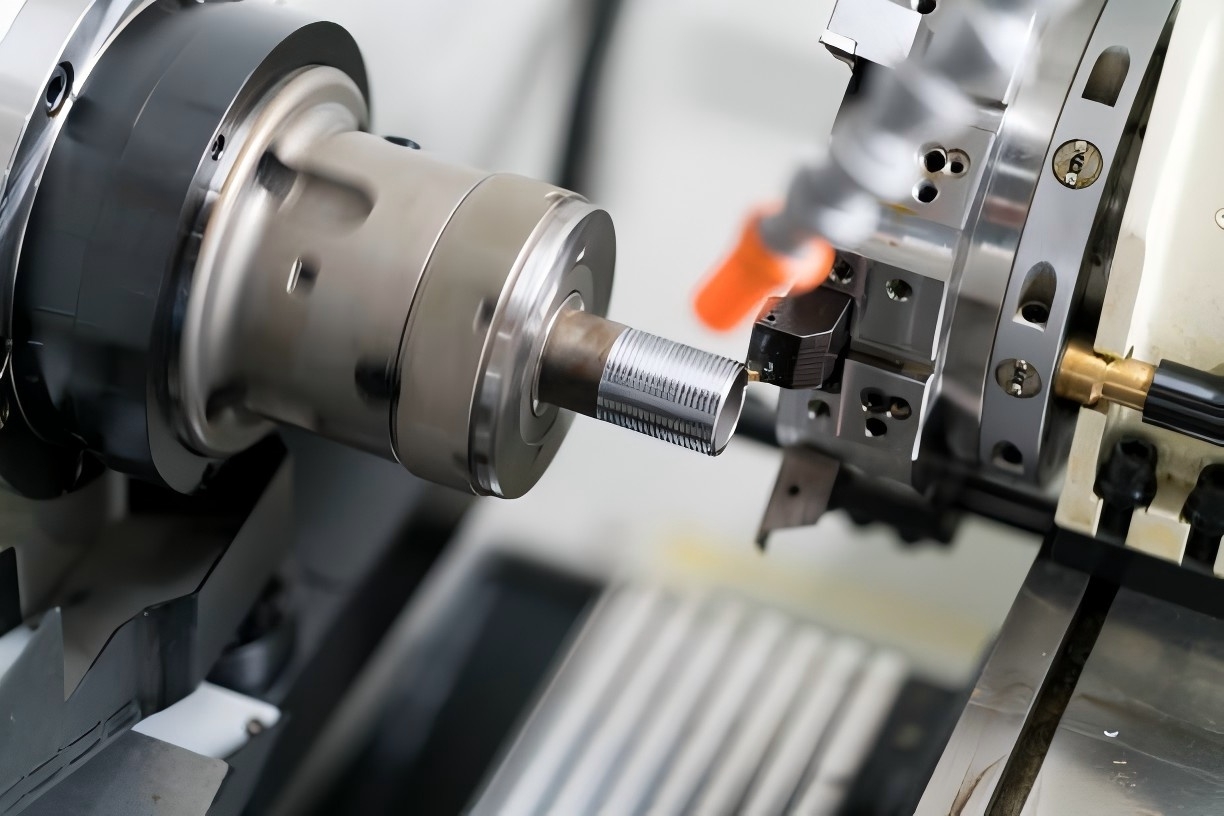

High processing accuracy

One of the main advantages of a five -coordinate processing center is its ability to ensure high accuracy of processing. This is achieved due to the fact that the machine is able to control the position of the tool in five axes at the same time. Such accuracy is important for the manufacture of complex and exact details, especially in industries such as aircraft industry, automotive and medicine. The ability to avoid massive operations of changing tools and reinstalling workpieces reduces the number of possible errors, thereby improving the repeatability and product quality. Thanks to the use of technologies, such as precision sensors and feedback systems, modern five -coordinate centers are able to achieve tolerance, measured literally in micron, which makes them an ideal tool for the production of high -precision components.

Reducing production time

Thanks to the ability to process the part from various sides without the need for manual overflow, five -coordinate centers significantly reduce the total time of the production cycle. This allows not only to increase productivity, but also to significantly reduce labor costs, which ultimately improves the economic efficiency of the enterprise. The integration of automated management systems of production processes allows five coordinate centers to perform many operations in continuous mode, which reduces the time spent on tuning equipment and preparing workpieces. As a result, you can significantly increase the volume of products without increasing production space or hiring additional personnel, which is an important factor for small and medium -sized enterprises that strive to increase their competitiveness in the market.

The possibility of processing complex shapes

The five -coordinate processing center opens the way to create products with more complex geometric shapes, which is difficult, and sometimes it would be impossible to make on more traditional machines. This gives designers and engineers more freedom in the design of innovative solutions, which, in turn, contributes to the development of new products and technologies.A five -coordinate processing centerAllows you to make products that require a highly respected arrangement of holes or complex surface shapes, such as aerodynamic elements or medical implants that provide perfect fitting and functional properties. This is especially true for the defense industry, automotive and other industries, which requires products that provide the highest indicators of strength, reliability and safety.

Improving economic efficiency

The economic efficiency of five coordinate processing centers is also manifested in reducing the cost of manufactured products. This becomes possible due to a decrease in the technological waste of material during processing and reducing the number of operations. The functionality of such centers involves the integration of various stages of processing into one integrated process, which minimizes the need to use additional tools or equipment.A five -coordinate processing centerIt achieves this thanks to the complex processing programs and the possibility of variability of tools, which allows you to choose the best operating modes to complete each specific task. Due to this, there is a decrease in the costs of the purchase of materials, electricity and the time of employees, and the wear of equipment is also reduced, which facilitates the long -term perspective of the return to investments.

Improving working conditions

The use of five coordinate centers also contributes to the creation of safer and comfortable working conditions for operators. Providing automated control and minimizing the need for manual settings and interventions, such machines reduce the risk of injuries and errors caused by the human factor. This allows operators to focus on quality control and optimization of processes, and not on laborious routine tasks. Monitoring systems of equipment and remote control, integrated into modern five -coordinate centers, make it possible to quickly respond to changes in operating acts, which ensures an additional level of safety and reliability of production. Thus, the introduction of five -coordinate centers into production processes not only can increase the efficiency and quality of products, but also significantly improve labor conditions at the enterprise.

Innovation and development

Five -coordinate processing centers play a key role in the development of innovation and the introduction of new technologies in industry. They provide opportunities for the use of the latest engineering solutions and production methods that expand the horizons of mechanical processing capabilities. Thanks to the support of complex software that facilitates the adjustment process and the creation of processing programs, these centers contribute to the accelerated implementation of innovative development in production. This, in turn, allows enterprises to remain competitive in the conditions of a constantly changing market and increase their adaptation ability. The introduction of five -coordinate technologies opens up new prospects for startups and small engineering companies, allowing them to occupy more stable and confident positions in the market, developing unique products and services that previously seemed inaccessible.