How to choose a Pyatoose CNC machine for production?

2025-01-11

The choice of a five -axis machine with a numerical program (CNC) for production is a key step for companies striving to increase the accuracy and efficiency of their production processes. In the modern world of such machines there are many options, and the question becomes more and more important: how to choose exactly the machine that will fully satisfy your needs and tasks? The selection process includes many factors, such as the technical characteristics of the machine, its performance, software, manufacturer support and much more. In this article, we will examine in detail all the aspects that will help you make a balanced decision and choosePyatoose CNC machine, in the best way meets your specific requirements.

Technical characteristics

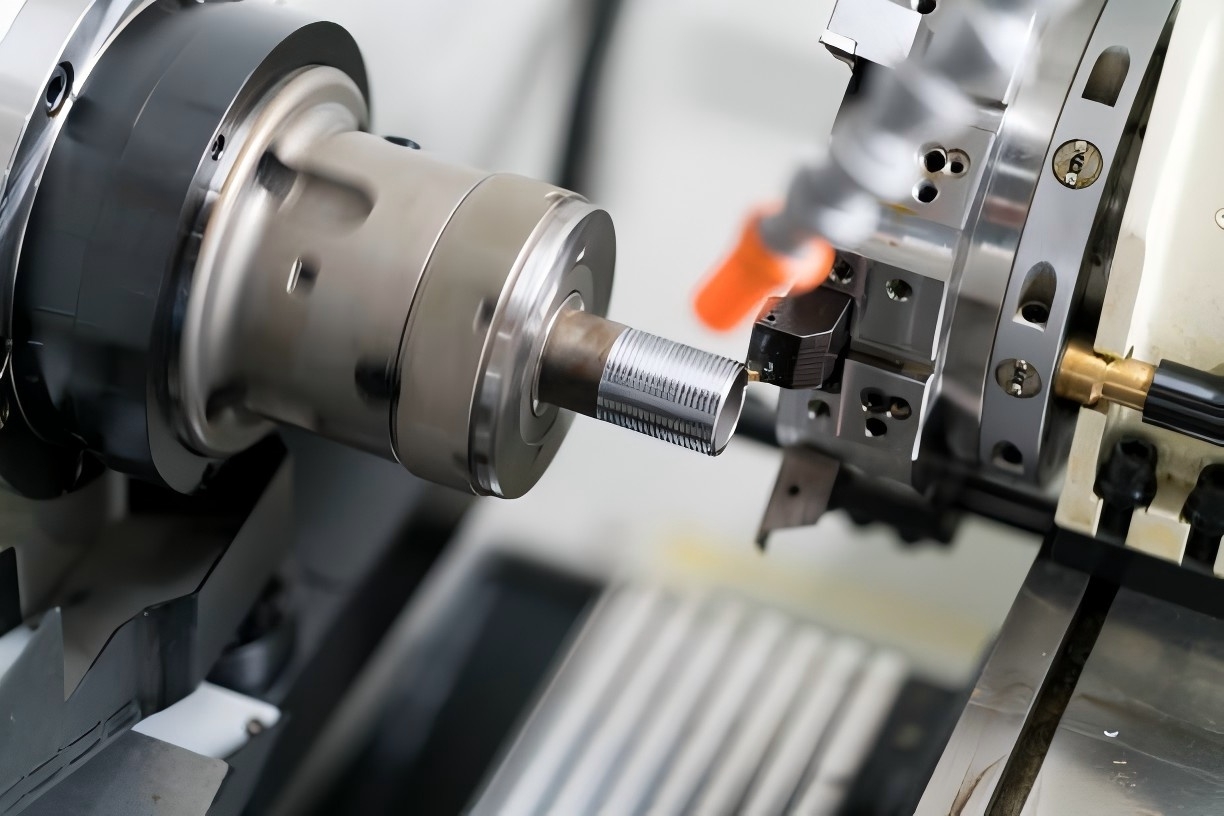

One of the first aspects that should be taken into account when choosing a five -axle CNC machine is its technical characteristics. It is important to determine which materials you are going to process, and in accordance with this to choose a machine with the corresponding spindle power and a speed range. This will help to ensure high performance and processing quality. The dimensions of the working area also play a decisive role, as this determines the maximum dimensions of the workpiece, which can be processed without the need for re -installation. Parameters such as the rigidity of the design of the machine, the accuracy of positioning and the maximum load on the table are also critical factors, especially for complex and thin operations.

Additionally, you should pay attention to the machine control system. The latest models are often equipped with advanced CNC systems that provide a simple and intuitive interface that allows you to quickly configure and optimize production processes. Such systems provide the ability to integrate with CAD/CAM software, which greatly simplifies the path from design to production. All these elements should be perfectly balanced to maximize the potential of the selected machine.

Performance and speed

The performance of the Pyatopian CNC machine is determined by its ability to process a certain amount of parts in a certain period of time without loss of accuracy and quality. One of the critical parameters is the processing speed, which directly affects the production time of one part. It is important to evaluate the capabilities of the machine when processing various materials, since the choice of the most suitable model for specific needs depends on this.

We must not forget about the stability of equipment at high loads. The machine should be able to process parts at maximum speeds without overload and with minimal vibrations that can adversely affect the quality of the final product. The well -thought -out design and use of high -quality materials ensure long -term stability and reliability of equipment. Pay attention to user reviews and test the machine before buying to make sure of its appropriate performance for your production.

Software and integration

Modern Pyatical CNC machines are equipped with complex software, which is responsible for managing all processing processes. The choice of a suitable program is no less important than the choice of the machine itself. Make sure that the software supports all the necessary functions, including the creation of complex trajectories, simulation of processing and the possibility of quickly adjusting the program. Such capabilities are possessed by systems in the market that provide not only high processing accuracy, but also ease of operation for the operator.

Integration with CAD/CAM systems is another important aspect that simplifies the entire process from design to the final processing of the product. This can significantly reduce the training time and minimize the possibility of errors arising from the human factor. ChoosingPyatoose CNC machine, make sure that it supports not only the current software, but also provides for the possibility of updating and adaptation to new technologies and time challenges.

Support and maintenance

For durable work and maintaining high productivity of the machine, professional support and regular maintenance is critical. When choosing an equipment supplier, pay attention to the level of service that he offers. Warranty obligations, accessibility of spare parts, staff training and the possibility of remote diagnostics - all this should be provided for by your agreement with the supplier.

The presence of a reliable and fast service is important no less than all other characteristics of the machine, especially with intense production cycles, where everyone can simply cause significant losses. Additionally, learn about the possibilities of modernizing equipment, this will help extend its service life and maintain relevance in the rapidly changing technology market.

Cost and payback

Of course, when choosing a five -axle CNC machine, the cost plays an important role. But it is worth considering the purchase of such equipment not as expenses, but as investments in the future of the company. Evaluate the payback of the equipment, hoping how much time it will take to make a new technique to make a profit. Consider not only the price of the machine itself, but all the related expenses: installation, staff training, acquisition of software, and so on.

Many manufacturers provide the possibility of leasing or installments, which allows you to more flexibly approach the issue of financing without too much the load on the company's budget. Rationally approach the calculations and make decisions based on the long -term perspective of the growth and development of your enterprise.

Completion of choice

The choice of the correct five -axle CNC machine is a complex and multifaceted process that requires attention to many details. Studying technical characteristics, performance and performance assessment, as well as the reliability of the supplier and support - all these are key factors that will help make the right choice. Understanding your unique needs and market capabilities will achieve maximum returns from the selected equipment. Analyze all available offers, consult with experts and make balanced decisions so that your business can successfully develop and conquer new markets.