How to choose a 5-coordinate CNC center for production?

2025-02-08

The choice is suitablea five -coordinate processing center with CNCIt is a key step for any enterprise striving to increase its production flexibility and efficiency. Modern industrial technologies require speed, accuracy and adaptability, and it is precisely such characteristics that are provided using the pale coordinate centers. In this article, we will consider the main aspects that must be taken into account when choosing the perfect CNC of the center in order to satisfy all production needs and optimize costs. Our tips will help to conduct a comprehensive market analysis and determine which center is suitable for your business in the best way.

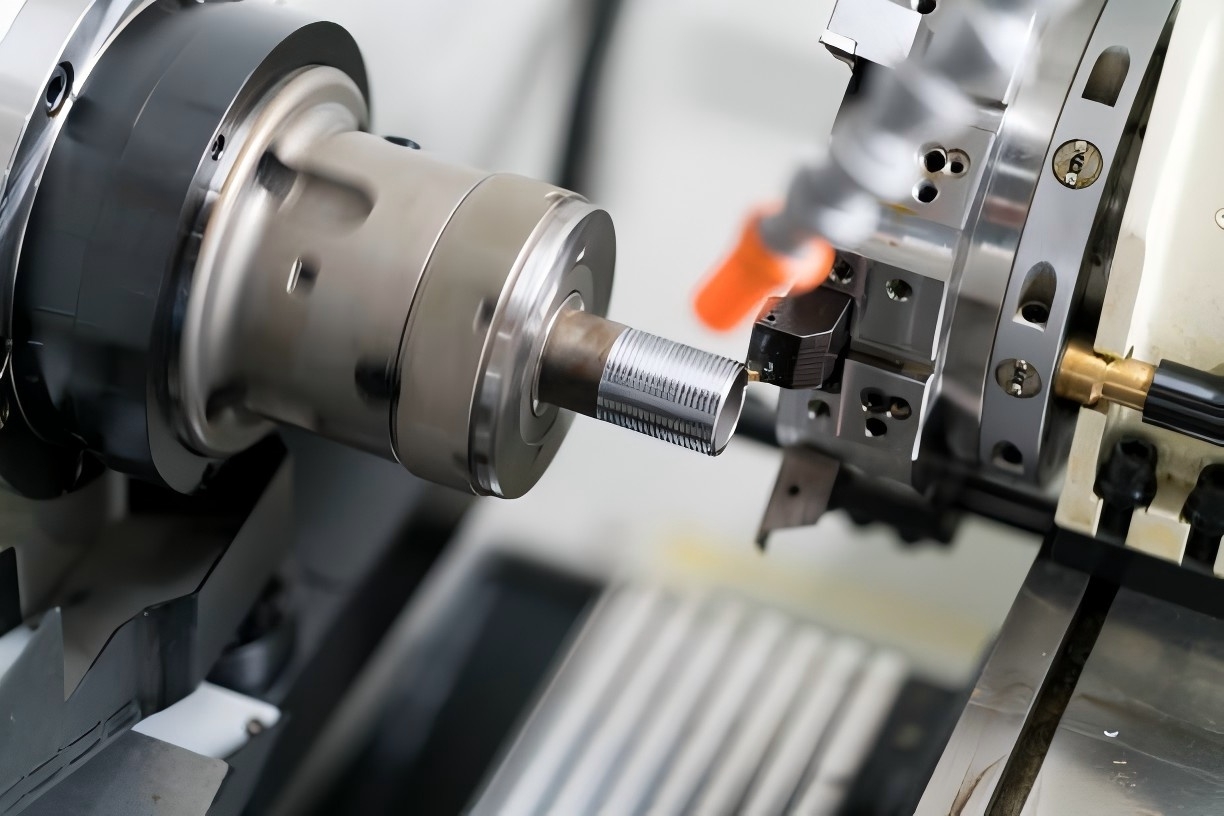

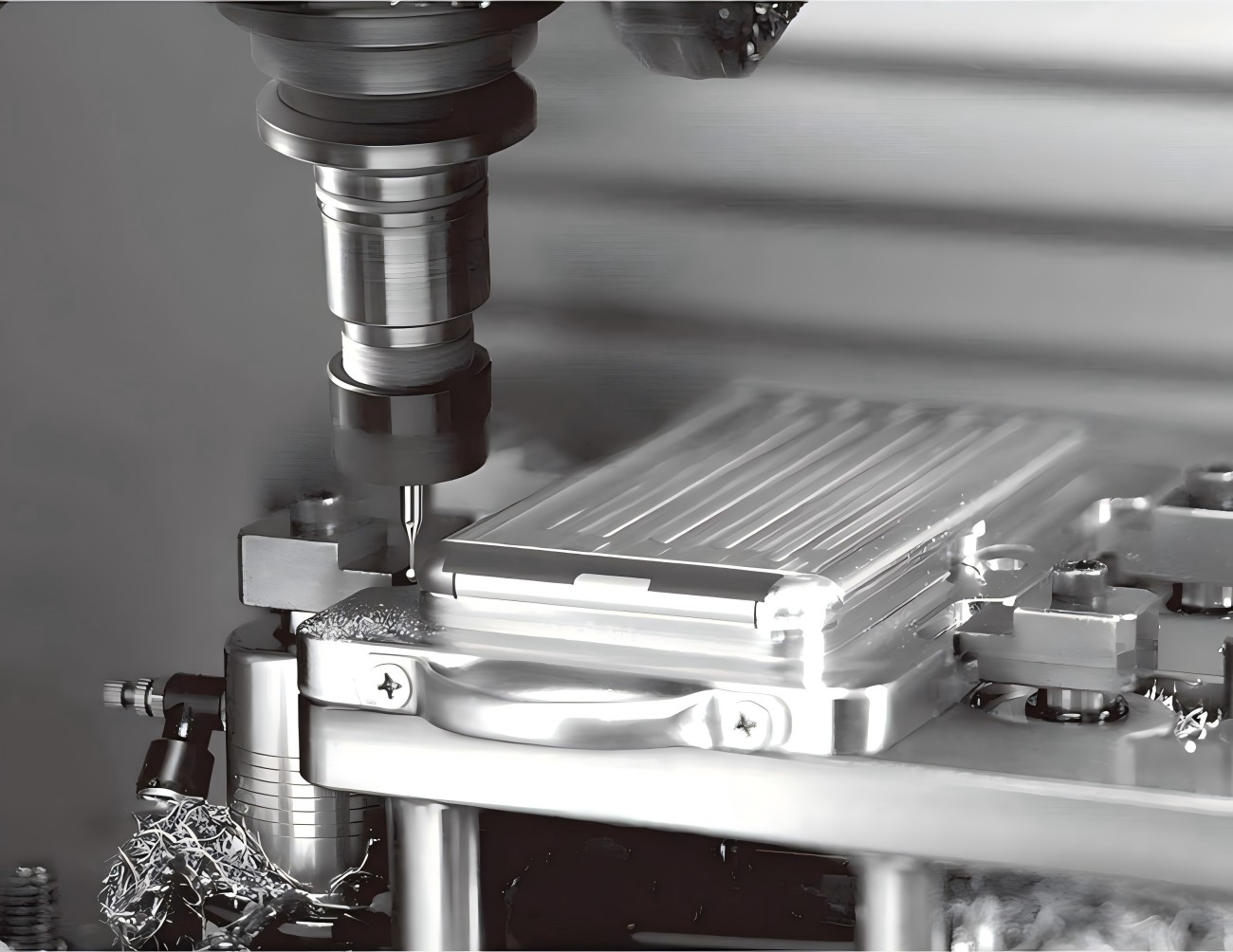

Technical characteristics of equipment

When choosinga five -coordinate processing center with CNCIt is necessary to pay attention to its technical characteristics. The power of the spindle and the number of revolutions per minute play an important role in maintaining the accuracy and speed of processing. The accuracy of the axes, the stability of the work and the volume of the machine are all important indicators. Recognition of the selected characteristics will improve production processes. Do not forget to take into account the manufacturer: different brands offer various sets of opportunities for its customers.

Correspondence of products

The compatibility of the CNC center with an existing technological process is a factor that should not be overlooked. Make sure that the selected equipment meets all your requirements for the size and difficulties of the workpieces, which is especially important when performing accurate and complex operations. 5-coordinate centers reduce the number of workouts and operations, significantly facilitating the process of production of complex products.

Financial aspects and profitability

Another important aspect is the costa five -coordinate processing center with CNC. Analyze not only the initial investments, but also the potential costs of maintenance and operation. The development of a financial profitability plan may also include possible savings from increasing performance and reducing the time for processing parts. It is worth noting that it does not mean better, but a higher initial cost can pay off due to the high operational qualities of the machine.

Suppliers and manufacturers

The choice of a proven supplier is as important as the choice of equipment itself. Make sure that the manufacturer offers sufficient support and consultations, especially at the initial stage of equipment operation. The reputation of the company in the market, the availability of service centers and the availability of spare parts will be decisive factors when choosing a partner. Long -term relationships with a reliable supplier will be able to make the purchase and use process more smooth and successful.

Maintenance and support

Another significant aspect is the quality and frequency of equipment maintenance. Be sure to pay attention to the services for service and warranty from the manufacturer and supplier. The possibility of operational repairs and the presence of spare parts can become critical in case of breakdown, affecting the duration of the equipment downtime and, as a result, the overall level of production productivity.

Integration into existing processes

It is equally important to evaluate how smooth the new technique is integrated into your current production environment. Compatibility with existing machines and software can affect the efficiency of work. Develop an integration plan covering all stages from delivery and installation to full commissioning. Careful preparation will save you from surprises and help to achieve faster and effective commissioning.

Moments such as the right choice and integrationa five -coordinate processing center with CNCThey are the key to the successful modernization of your production. All of these factors will help make a conscious choice and maximize the possibility of modern equipment to increase the efficiency of the company. To receive additional information and consultations, you can visit the siteFive -hobby processing center with CNC, where technical solutions are presented for various needs of your production.