How do five CNC axes affect environmental stability?

2025-01-25

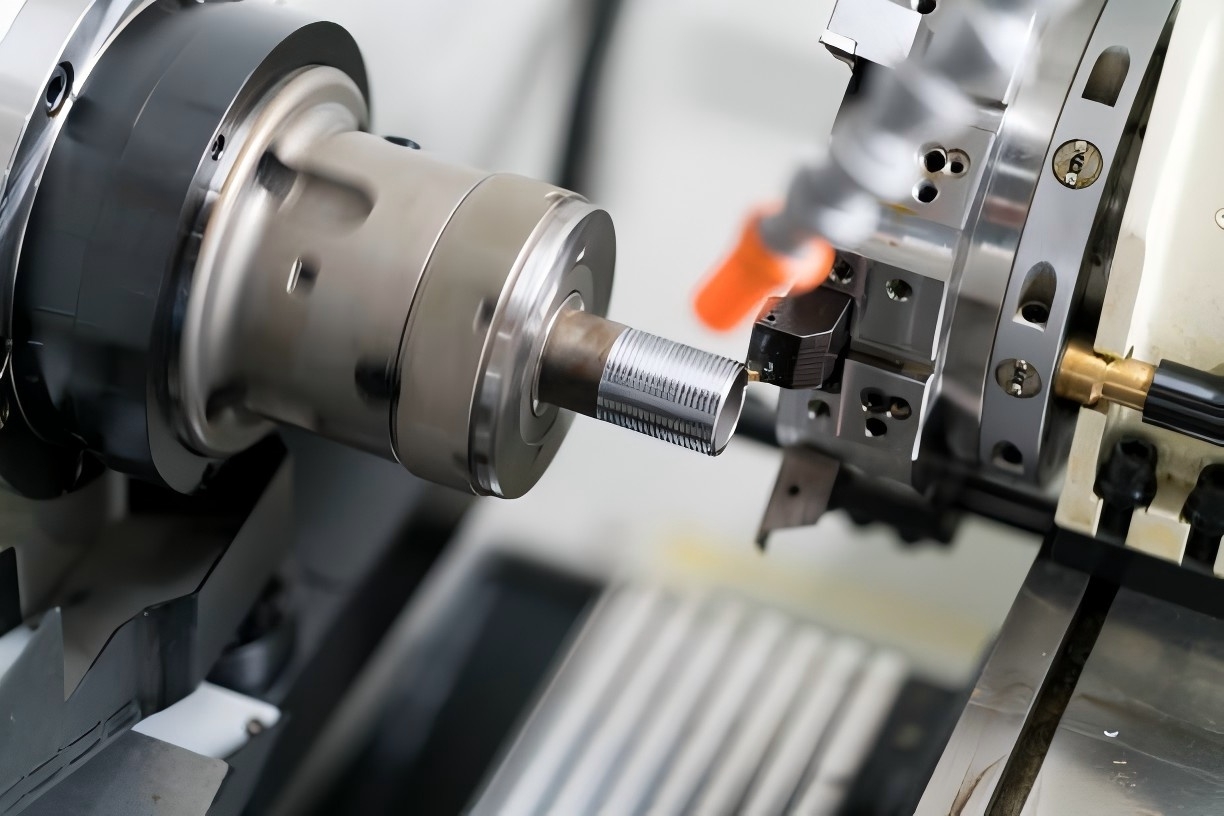

In the modern world, industry is faced with problems of reducing the negative environmental impact. In this regard, technologies based on numerical software management (CNC) play a key role in increasing the environmental stability of production processes. Particularly distinguished machines with five CNC axes, which are increasingly used in various industries. They allow us to optimize the production process, reducing the amount of waste and energy. These advantages make Pyato -axial CNC machines not only with an effective tool for processing materials, but also an important factor in the struggle for environmental stability. We will talk about how exactly five -axial CNCs have a positive impact on the ecology.

Technological advantages of Pyatoose CNC

Pyato -axial CNC machines provide unique capabilities in the manufacturing industry. One of the main advantages of such machines is their ability to arbitrarily change the processing angle, which reduces the number of necessary rearrangements of parts. This leads to a significant reduction in the time of processing and a decrease in energy consumption, which has a beneficial effect on the environmental situation. Five -axial CNCs provide high accuracy and quality of surface processing, which minimizes the amount of marriage and waste. Moreover, this technology reduces the need for additional operations, reducing the use of auxiliary materials and resources.

Reducing energy consumption

The most important aspect of the impact of Pyato -ose CNC on environmental stability is associated with a decrease in energy consumption. Due to the possibility of simultaneous processing of several sides of the part, these systems significantly reduce the total time of the production cycle. This, in turn, leads to a significant decrease in energy consumption per unit of products. Optimization of processing routes and a decrease in the number of tops also helps to reduce electricity costs. Thus, the introduction of these technologies allows not only to save on expenses, but also to reduce the carbon investigation of the production enterprise.

Reducing waste in production

Pyatical CNC machines are maximally used to optimize materials, minimizing the amount of waste in the production process. Due to the high accuracy of positioning and movement, such machines allow for the maximum use of blanks, reducing the amount of remaining material and waste.Pyatoose CNCIt provides fewer other waste, as less inconscious and tools are required due to more complex and accurate processing. The reduction in the amount of waste not only reduces the cost of recycling, but also reduces the impact on the environment. This makes Pyato -axial CNC machines attractive for companies striving for environmentally friendly production.

Increase in the life of the tools

Pyato -axis CNC systems use more complex trajectories of the tool, which reduces the resistance of the cutting and wear of the tool. Using such machines, enterprises can reach a longer service life, thereby reducing the cost of replacing it and disposal. This leads to a decrease in the consumption of resources used to produce new tools, which ultimately reduces the environmental trace of production. The increased service life also reduces the frequency of production stops, increasing the overall efficiency and reducing energy consumption.

Compliance with environmental safety standards

Modern production enterprises are required to comply with various environmental standards and norms. In this contextPyatoose CNCIt becomes an important tool for achieving the declared goals in the field of sustainable development. These technologies allow enterprises not only to increase efficiency, but also to reduce their negative impact on the environment, which is important for compliance with international environmental safety standards. The introduction of machines with five CNC axes helps companies improve their ecological profile and strengthen the reputation in the eyes of consumers, investors and regulators.

Prospects and future development

With an increase in interest in environmentally friendly production technologies,Pyatoose CNCIt becomes a central figure in the stability of the sustainability of modern enterprises. It is expected that in the future the use of these technologies will only increase, leading to a further decrease in energy consumption and waste. Studies in the field of improvement of the CNC Pyato -ose CNC machines open new horizons for a more accurate management of resources and reduce environmental impact. Such development will contribute to further integration of stable production methods and the creation of a more environmentally friendly future for industry as a whole.

As a result, the use of the CNC Pyatopo -axial machines significantly affects the increase in environmental stability, providing more efficient use of resources and reduce the negative impact on the environment.