Why are we

2024-11-12

Work experience for more than 20 years.

A plant with an area of more than 75,000 square meters and more than 500 employees.

Annual production capacity of more than 5,000 sets

Strict quality control system.

Professional production management system ISO9001.

Delivery on time

Great quality and reasonable price.

Strict confidentiality for customers.

Ideal after -sales service system

It is exported to more than 20 countries.

TAIXING was born out of the desire to provide you with available and high -quality CNC equipment.

Ensuring ultra -high expenditures is our biggest advantage, as well as our goal and motivation for constant struggle over the past 20 years.

Compared to Taiwanese and Japanese CNC machines, our cost is only 50-70%, while the performance of our CNC machines can reach 95-120%, and the service life is more than 20 years. This is due to a strong Chinese production experience, a fulfilled logistics system and a perfect supply management system for more than 20 years.

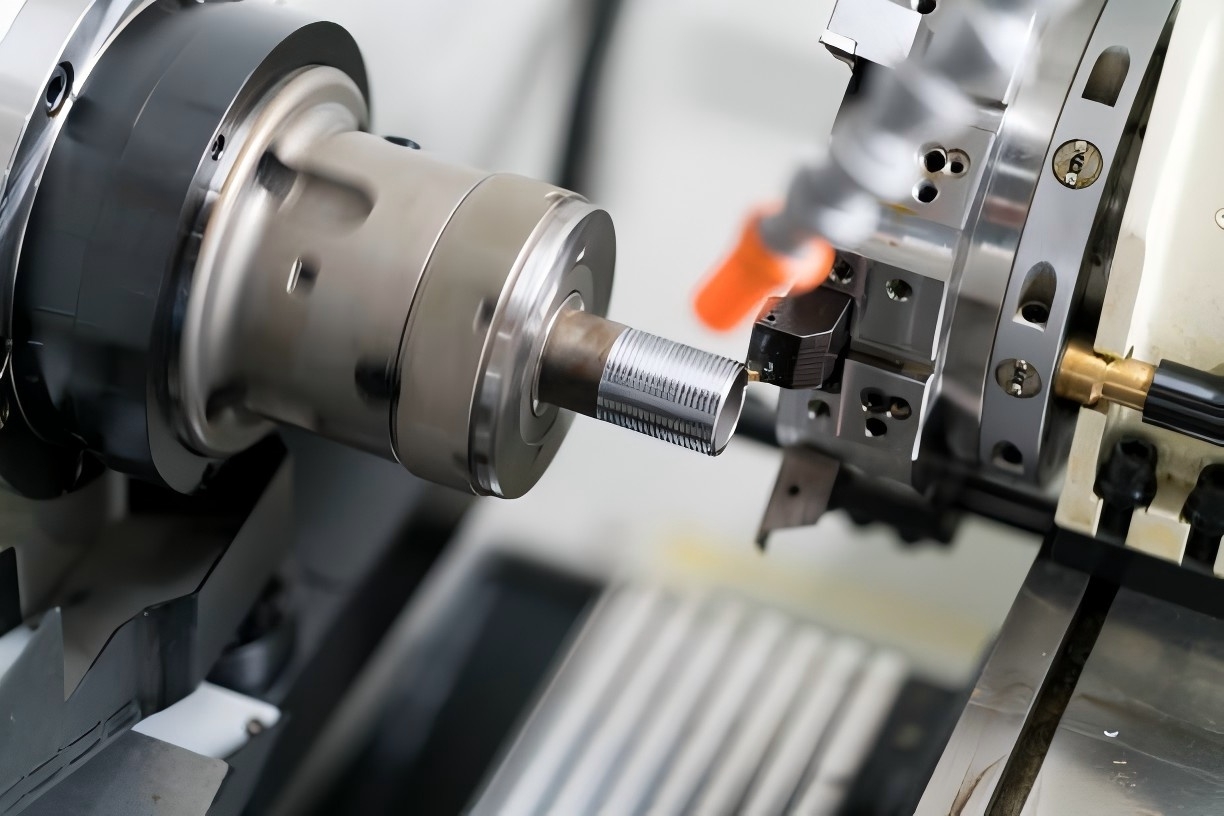

Our production equipment

Nicholas portal processing center

Taiwanese grinding machine Freeport

Japanese Eagnage and milling machine TOSHIBA

Foundry

Our studio

production of vertical processing centers.

this place for the production of vertical processing centers

Key spare parts:

To guarantee that we provide you with 100% reliable products, we choose the key spare parts for you from world -famous manufacturers who have been carefully selected and have passed our strict control system of the supply chain.

The main components of the TAIXING with CNC:

Ponsky ballpoint screw and roller guide Thk, German optical grille Heidenhain.

Japanese SHIMPO gearbox, German chain LGUS.

Schneider Taiwan high -speed pressure cylinder

Japanese ATC LED LED with Servigator

Italian gearbox BF, Taiwan, milling corner head Yangming

German cable Leoni, Japanese oil lubricator

Linear guides with recirculation rollers have significant advantages.

Linear guides with recirculation rollers have a preliminary tightness, which ensures the absence of a backlash between the sliding surfaces.

This not only increases rigidity, but also increases accuracy and stability. The linear guide friction coefficient is low, so it can provide the repeating accuracy of positioning and the accuracy of positioning during quick movement.

Taixing installs Japanese linear guides Thk. The driving environment of roller linear guides is linear and surface rolling contact, and the moving area of the ball linear guides is the contact of the point surface.

Thus, roller linear guides have higher rigidity and higher accuracy than ball linear guides. Square guides require a gap between the sliding surfaces to move. They have a large friction coefficient and are prone to sticking, which can lead to errors during processing.

Mature and stable production technology:

You can enjoy the production team consisting of more than 300 production line employees in the first department of cars, the first assembly department of cars and the second assembly department, 60% of which have more than 10 years of experience to provide you with satisfactory services. Thus, our technical processing is very stable, production efficiency is always high, and the percentage of products before sending is 100%. Such a full production process can help you minimize costs.

Production process:

Use the collimator to check the straightness of the linear guide.

Use a control rod to calibrate straightness and alignment (span) between the base of the engine and the end base.

Using the marble line, check the parallelism of the left and right guides and make sure that they are parallel to the reference guide.

Checking the parallelity between the Zid axis Z and the axis of the spindle.

Cleaning process

The process of laying the oil circuit